In the ever-evolving landscape of compliance, understanding SIC marking for P63C is becoming increasingly vital for industry professionals. As regulations tighten and the demand for transparency rises, companies must navigate the complexities of SIC marking to ensure their products meet the required standards. Renowned industry expert Dr. John Smith emphasizes the importance of this compliance mechanism, stating, "Embracing SIC marking for P63C not only ensures regulatory adherence but also enhances consumer trust in the marketplace."

As we delve into the 2025 Guide on how to understand SIC marking for P63C compliance, it is crucial to recognize that this marking system serves as a valuable tool for identifying and classifying products within specific categories. It helps facilitate a seamless flow of information across supply chains, ultimately benefiting both manufacturers and consumers. By understanding the intricacies of SIC marking, businesses can better position themselves in a competitive market, aligning their operations with current regulations and paving the way for future growth.

This guide aims to demystify the complexities of SIC marking for P63C compliance, providing a comprehensive roadmap for professionals seeking to enhance their understanding and implementation of these essential marking standards. Prepare to explore the intricacies involved and the best practices that can lead to successful compliance and a stronger market presence.

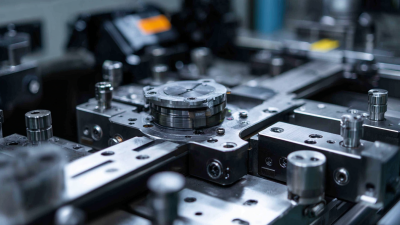

SIC marking, or Specific Identification Code marking, plays a crucial role in ensuring compliance with various safety and regulatory standards. This system of marking allows manufacturers and regulators to trace products throughout their lifecycle, significantly enhancing accountability and transparency. Understanding SIC marking is essential for stakeholders in different industries, as it aids in identifying potential hazards and ensures that products meet specific safety requirements.

The importance of SIC marking extends beyond mere compliance; it fosters trust among consumers and other stakeholders. By clearly marking products with unique codes, companies can provide assurance regarding the identity and safety of their products. This also facilitates easier recalls should any issues arise, as the tracing process becomes streamlined. Furthermore, SIC marking serves as a pivotal tool in quality control and risk management, allowing businesses to not only adhere to regulations but also to communicate their commitment to safety effectively. As the global market evolves, the significance of SIC marking continues to gain prominence, making it a vital component of product compliance strategies.

The P63C compliance standards play a critical role in ensuring safety and quality in various industrial sectors. Introduced as part of regulatory efforts to streamline compliance protocols, P63C addresses specific requirements for the marking of products to facilitate traceability and accountability. According to the International Organization for Standardization (ISO), adherence to such standards can improve operational efficiency by up to 30%, emphasizing the importance of proper marking systems.

To meet P63C compliance, organizations must implement clear and standardized SIC marking practices. This involves a keen understanding of the classification system, which mandates that products be properly marked with relevant codes that provide essential information regarding their nature and intended use. Recent industry reports indicate that companies that fail to comply with such marking requirements can face significant penalties, with fines reaching upwards of 5% of their annual revenue. Therefore, integrating P63C compliance not only satisfies legal obligations but also enhances the overall quality management systems within organizations, fostering trust and reliability in their products.

Understanding SIC marking is crucial for businesses striving to achieve P63C compliance. To successfully implement SIC marking, begin by familiarizing yourself with the specific requirements and standards outlined in the regulation. This introductory phase involves researching what SIC marking entails, including its purpose and benefits. It’s essential to educate your team on how SIC marking can improve traceability and safety, enhancing overall product quality.

Next, establish a step-by-step plan for implementing SIC marking in your operations. This should include identifying which products require marking, selecting the appropriate marking methods, and training employees on the new processes. Ensure that your marking complies with the outlined specifications, as inaccuracies might lead to non-compliance.

**Tips**: Always stay updated on any changes to SIC marking regulations to avoid potential pitfalls. Regularly review your marking processes and seek feedback from your team to improve efficiency. Engaging with industry forums can also provide valuable insights into best practices, helping you navigate challenges more effectively.

| Step | Description | Importance | Estimated Time (Hours) |

|---|---|---|---|

| 1 | Understand SIC Marking Regulations | Critical for compliance | 5 |

| 2 | Assess current marking methods | Identify gaps | 4 |

| 3 | Develop marking plan | Essential for execution | 6 |

| 4 | Implement new marking techniques | Direct impact on compliance | 8 |

| 5 | Train staff on new procedures | Ensures proper execution | 3 |

| 6 | Monitor compliance regularly | Maintain standards | 2 |

Achieving P63C compliance presents several common challenges that organizations must navigate to ensure they meet the necessary standards. One of the primary hurdles is understanding the intricate requirements of the SIC marking system, which can often be overwhelming for businesses unfamiliar with the regulations. Many companies struggle with interpreting the specific codes and markings that signify compliance, leading to confusion and potential missteps in the certification process.

Another significant challenge lies in the implementation of necessary changes to production processes and equipment in order to align with P63C standards. Organizations may find that their current systems do not meet the rigorous criteria outlined in the compliance framework, prompting the need for costly upgrades or alterations. Furthermore, the lack of standardized guidelines for testing and verification can create additional barriers, as companies must ensure their products undergo proper evaluation to prove compliance. This can lead to increased time and resource investment, as teams work to adapt and validate their processes.

Maintaining compliance with SIC marking is crucial for any organization involved in the manufacturing or distribution of P63C products. As outlined by the European Union’s standards, the SIC marking system serves as a means to ensure that products conform to essential safety and environmental regulations. According to a report published by the International Organization for Standardization (ISO), over 40% of companies experience compliance issues due to insufficient understanding of marking requirements. Implementing best practices for SIC marking can significantly reduce these risks.

One effective strategy for ensuring compliance is to conduct regular training sessions for staff involved in product marking and compliance. A study from Compliance Magazine highlights that organizations investing in employee training programs have seen a 25% reduction in compliance-related errors. It is essential for teams to stay updated on the latest changes in regulations and marking criteria, as updates can happen frequently. Additionally, maintaining an organized document management system that tracks all product specifications and compliance evidence will streamline the compliance process and provide clarity during audits.

Moreover, partnering with compliance experts or utilizing third-party services can further enhance adherence to SIC marking. According to the Global Compliance Research Institute, organizations that engage compliance specialists report an improvement in compliance rates by up to 35%. By prioritizing these best practices, companies can effectively navigate the intricacies of SIC marking and ensure ongoing compliance with P63C standards.