In the rapidly evolving landscape of manufacturing and product distribution, compliance with industry standards has become more crucial than ever. The 2025 SIC Marking Manual serves as an essential guide for businesses striving to adhere to best practices in marking and identification processes. According to a recent report by the International Organization for Standardization (ISO), over 70% of manufacturers cite compliance as a significant factor influencing their operational strategies. The effective implementation of marking standards not only ensures regulatory compliance but also enhances supply chain traceability and product security.

As organizations navigate the complexities of global markets, understanding the intricacies of the SIC Marking Manual becomes imperative. The manual outlines critical practices that help businesses avoid costly penalties and streamline their marking processes. A comprehensive study by the Compliance Standards Institute highlights that companies adhering to established marking protocols witness a 30% reduction in compliance-related issues. This emphasizes the need for companies to invest time and resources into mastering the guidelines presented in the SIC Marking Manual, ultimately fostering a culture of accountability and excellence within their operations.

With the emphasis on safety and standardization, businesses that integrate the recommendations from the SIC Marking Manual into their operational workflows not only mitigate risks but also gain a competitive edge in the marketplace. The importance of staying informed about best practices in marking cannot be overstated, as it aligns with broader industry trends focusing on quality assurance and customer satisfaction. By embracing the guidance within the SIC Marking Manual, companies position themselves for sustainable growth and long-term success in an ever-demanding environment.

SIC marking, or "Symbolic Identification Code" marking, serves as a critical element in ensuring compliance within various industries. It is an essential method for identifying products throughout their lifecycle. By assigning a unique code to each item, companies can efficiently track and manage their inventory, enhance quality control, and facilitate easier communication between manufacturers and consumers. This marking system not only aids in the identification of products but also significantly contributes to brand integrity and consumer trust.

The importance of SIC marking extends beyond mere identification; it plays a vital role in regulatory compliance and safety assurance. Industries worldwide are increasingly required to adhere to stringent regulations regarding product safety and traceability. By implementing effective SIC marking practices, organizations can demonstrate their commitment to safety standards and reduce potential liabilities. Furthermore, clear and consistent marking helps streamline supply chain operations, ensuring that all stakeholders—from manufacturers to retailers—understand the product’s specifications and compliance status. This clarity fosters a safer and more reliable marketplace, benefiting businesses and consumers alike.

As businesses navigate the complexities of SIC marking, understanding the key compliance standards for 2025 is crucial. The SIC marking system plays a significant role in ensuring products meet regulatory requirements across numerous industries. According to a recent report from the International Compliance Organization, adherence to compliance standards can reduce the risk of product recalls by up to 30%. This underscores the importance of rigorous compliance programs in manufacturing and distribution processes.

In 2025, the compliance landscape is expected to evolve, integrating more advanced technologies and stricter regulations. The use of automated marking systems is projected to increase by 25%, enhancing both accuracy and efficiency. Companies that invest in cutting-edge marking technologies will not only ensure compliance but also streamline their operations. Additionally, aligning with standards set by organizations such as ISO and ASTM will be critical for businesses aiming to maintain competitiveness in the global market. As new guidelines emerge, staying informed and proactively adapting to these changes will be vital for long-term success.

| Compliance Standard | Key Requirements | Best Practices | Implementation Timeline |

|---|---|---|---|

| ISO 17665-1 | Sterilization of health care products | Regular audits and training | Q1 2025 |

| ISO 9001 | Quality management systems | Customer feedback integration | Q3 2025 |

| ISO 13485 | Medical device quality systems | Risk management processes | Q2 2025 |

| ANSI/ISO 9000 | Fundamentals of quality management | Continuous improvement strategy | Q4 2025 |

| ISO 14001 | Environmental management systems | Sustainability assessments | Q1 2025 |

Implementing SIC marking solutions is essential for manufacturing and distribution companies aiming to enhance traceability and compliance. A report by the International Organization for Standardization (ISO) indicates that over 80% of supply chain professionals believe that enhanced traceability significantly reduces risks associated with product recalls. By adopting best practices in SIC marking, businesses can ensure that they not only meet regulatory requirements but also bolster consumer confidence in their products.

One best practice is the integration of advanced marking technologies that improve the durability and legibility of the markings. According to a study by the Barcode and RFID Solutions Association, utilizing high-quality materials and modern printing techniques can increase the lifespan of SIC markings by up to 50%, which directly impacts efficiency in logistics and inventory management. Additionally, training employees on the importance of accurate marking and data entry fosters a culture of compliance, reducing human error and its associated costs in the supply chain.

Another crucial aspect is the establishment of a comprehensive marking system aligned with industry standards. Research by the Global Compliance Institute highlights that companies with standardized marking practices experience 30% fewer compliance issues compared to those without. By maintaining consistent SIC marking protocols, businesses can streamline their processes, minimize liability risks, and ensure they are prepared for audits and inspections, ultimately leading to sustained operational excellence.

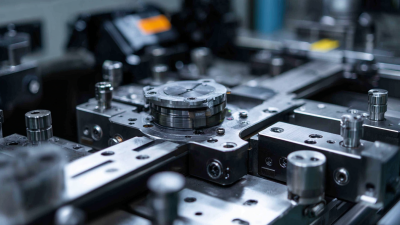

Technological advancements are reshaping the landscape of SIC marking procedures, driving organizations to adopt innovative practices for compliance and efficiency. Modern technologies such as automation, digital tracking systems, and advanced data analytics are enhancing the accuracy and speed of marking processes. Automated systems can significantly improve the consistency of markings, reducing human error and ensuring that all required information is captured effectively. This evolution not only streamlines operations but also aligns with the increasing demand for efficiency in production environments.

Moreover, the integration of IoT (Internet of Things) into SIC marking is revolutionizing how companies monitor and manage their marking procedures. By utilizing connected devices, organizations can track marking equipment performance in real-time, facilitating proactive maintenance and minimizing downtime. Additionally, data collected through IoT applications can inform strategic decisions, allowing companies to optimize their marking processes and ensure compliance with industry regulations. As these technological tools continue to evolve, they will undoubtedly play a crucial role in shaping best practices for SIC marking, ensuring that businesses can adapt to new compliance requirements while enhancing productivity.

As industries continue to evolve, the importance of SIC (Standard Industrial Classification) marking becomes increasingly paramount. The 2025 SIC Marking Manual highlights not only compliance requirements but also future trends that will shape marking strategies. Reports indicate that by 2025, sectors such as manufacturing and logistics may see a 20% increase in regulatory scrutiny, necessitating more robust compliance frameworks. Companies should prepare to integrate advanced technology to streamline their marking processes. The use of automated systems and IoT technologies can enhance accuracy in product tracking and ensure adherence to compliance standards.

Moreover, the growing trend of sustainability in manufacturing is influencing SIC marking compliance strategies. A recent study forecasts a 30% rise in demand for eco-friendly and traceable products by 2025, pushing businesses to adopt innovative marking solutions that align with environmental standards. Organizations are increasingly expected to demonstrate transparency and accountability, linking their SIC markings with sustainability efforts. Emphasizing accurate and accessible marking not only fulfills compliance obligations but also caters to the evolving consumer preferences towards responsible sourcing and manufacturing practices.

This chart illustrates the projected growth in compliance strategies for SIC marking from 2021 to 2025. The data reflects the increasing focus on compliance among different sectors, emphasizing the importance of adhering to marking standards.