In the precision manufacturing sector, SIC marking lasers have revolutionized the way industries approach marking and engraving. Researchers estimate that the use of SIC marking lasers can enhance productivity by up to 30%. This increase is attributed to their accuracy and efficiency, making them invaluable in sectors like automotive and electronics. Renowned industry expert Dr. Emily Carter emphasizes, "Investing in high-quality SIC marking lasers is non-negotiable for future-ready businesses."

Despite their advantages, challenges remain. Many businesses struggle with selecting the right laser for their specific needs. The range of options can be overwhelming. Users must balance precision with cost-effectiveness. Reports indicate that as many as 25% of companies underutilize their marking technology, leading to missed opportunities.

Understanding the landscape of SIC marking lasers is essential for any manufacturer aiming for success. With ongoing advancements and innovations, the market continues to evolve. Companies must remain vigilant and adaptable. Therefore, choosing the best SIC marking laser option in 2026 requires careful consideration and expert guidance.

SIC marking laser technology has transformed industries with its precision and versatility. These lasers can mark a wide range of materials, including metals and plastics. According to industry reports, the global market for laser marking is expected to reach $5 billion by 2026. This growth reflects the increasing demand for high-quality, durable marking solutions.

Applications for SIC marking lasers are diverse. They are used in automotive, aerospace, and electronics sectors, ensuring products meet stringent quality standards. This technology is capable of producing legible and enduring marks quickly. However, not all lasers provide the same performance. Some lasers may struggle with very fine details, leading to incompleteness in markings. This can affect traceability and quality assurance.

Data reveals that efficiency improvements in marking processes can reduce production times by up to 30%. Yet, businesses often overlook the importance of regular maintenance. Neglecting this can lead to inconsistent results. Additionally, the choice of laser should align with specific material requirements to avoid costly mistakes. Understanding these factors is crucial for leveraging SIC marking laser technology effectively.

Choosing the right SIC marking laser involves assessing various key features that directly impact performance. Precision and quality are paramount in laser marking applications. According to industry reports, lasers with wavelengths ranging from 1064 nm to 355 nm generally provide better engraving details. Shorter wavelengths often deliver finer marks, especially on metals and plastics.

Consider the power output of the laser. Higher wattage typically results in faster marking speeds. However, this can lead to overheating, affecting product quality. A balance between power and cooling systems is crucial. Understanding your material needs is essential; certain substrates react differently to various laser types. Data suggests that 32% of manufacturers face challenges in integrating lasers with existing processes due to these material discrepancies.

Another important feature is the user interface. Lasers with intuitive controls can reduce operator errors. Industry insights reveal that 60% of users favor systems with touchscreen interfaces. Yet, many still struggle with software compatibility. Regular training and updates can improve efficiency. Ultimately, careful consideration of these aspects will enhance operational excellence and product quality.

When it comes to high-quality laser marking, precision is key. In 2026, several models stand out for their reliability and performance. These devices excel in various applications, including metal marking and plastic engraving. Users often report impressive results with minimal adjustments. The ability to produce clean, detailed marks is essential for many industries.

Choosing the right model can be challenging. Factors like power, speed, and marking depth matter significantly. It's important to assess your specific needs before making a decision. Consider the materials you’ll be working with. Each laser has its strengths and weaknesses. Do thorough research and seek advice from experienced users.

Tips: Always test your chosen model on various materials. This helps in understanding its performance. Don't overlook maintenance; it can affect marking quality over time. Lastly, keep an eye on user reviews. They can offer insights into real-world performance that specifications often miss. Trust your gut on which features are truly essential for your projects.

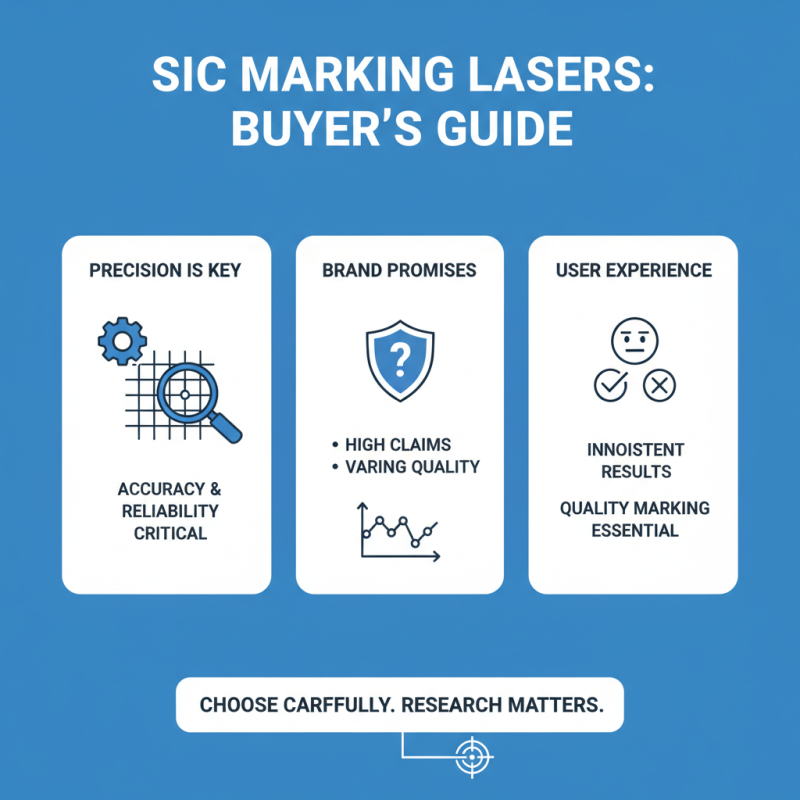

When looking for SIC marking lasers, several factors come into play. Precision is paramount. Various brands offer lasers that promise accuracy and quality. However, not every option lives up to the claims made. Users often report inconsistent results. This can lead to frustration, as quality marking is essential for various applications.

In a comparative analysis of market options, features vary significantly. Some lasers excel in speed, while others focus on engraving depth. The learning curve can be challenging too. Beginners may struggle to grasp the technology quickly. This adds another layer of complexity when selecting the right marking system. It’s important to consider not just the specifications, but also user feedback.

Additionally, maintenance can be a concern with these devices. Some lasers require frequent calibration, which can disrupt production. Users should weigh these factors before making a choice. Spending time to research and reflect on the options can lead to better decisions. Precision and quality are crucial, but the user experience plays a vital role as well.

The landscape of SIC marking laser technology is evolving rapidly. Innovations are pushing boundaries in precision and quality. Advanced algorithms improve engraving speed and accuracy. Enhanced software interfaces make operation easier. Real-time monitoring systems allow for immediate adjustments during production. Yet, challenges remain. Not every system integrates seamlessly with existing setups.

Another trend is the miniaturization of laser systems. Tools are becoming more compact without sacrificing performance. This allows integration into smaller manufacturing environments. However, cost remains a barrier for many businesses. Companies must consider their budgets when adopting new technologies. Moreover, user training can lag behind advancements, creating inefficiencies.

Sustainability is also becoming critical. Eco-friendly options are in demand. Manufacturers are exploring ways to reduce waste. This is not without its difficulties. There’s a balancing act between performance and environmental impact. As technology continues to advance, companies must reflect on their practices. The future of SIC marking lasers is promising, but it requires careful navigation of these evolving trends.