In today's fast-paced business environment, the need for precision and efficiency has never been greater. As companies seek innovative solutions to enhance their operations, box laser technology has emerged as a powerful tool that can transform various industrial processes. Leveraging the high precision and versatility that box laser systems offer, businesses can optimize their manufacturing capabilities, reduce material waste, and improve overall productivity.

The application of box laser technology spans numerous sectors, from automotive to aerospace, and even into the realm of creative design. This technology allows for intricate cutting, engraving, and marking tasks with unparalleled accuracy, making it an invaluable asset for any business looking to maintain a competitive edge. As we delve deeper into the advantages of box laser technology, it becomes clear that its implementation can lead to significant improvements in both the quality of products and the efficiency of production workflows.

By choosing box laser systems, companies stand to benefit not only from improved operational efficiency but also from enhanced flexibility in handling diverse materials and designs. This introduction will explore the compelling reasons why investing in box laser technology is a strategic decision that can drive business growth and innovation in the modern marketplace.

Box laser technology has emerged as a pivotal tool in modern industry, offering a plethora of advantages that enhance operational efficiency and product quality. One significant benefit is precision. The advanced optics and laser systems utilized in box lasers enable businesses to achieve exceptionally accurate cuts and engravings, minimizing material waste and eliminating the need for extensive post-processing. This precision not only improves the end product but also reduces production time, allowing companies to meet tight deadlines with ease.

Moreover, box laser technology is known for its versatility. It can be applied across a range of materials including metals, plastics, and fabrics, making it ideal for diverse industries such as manufacturing, automotive, and textiles. Businesses can easily adapt their processes to meet varying demands, providing a competitive edge in an ever-evolving market.

Tips: For businesses contemplating the switch to box laser technology, it's essential to assess your specific needs and material types. Investing in training for your team can also maximize the benefits of this technology, ensuring that your operations run smoothly and efficiently. Furthermore, consider collaborating with experts in the field to tailor the technology to your requirements, thereby enhancing productivity and innovation.

Box laser technology has become an essential tool across a variety of sectors due to its precision, versatility, and efficiency. In the manufacturing domain, box lasers play a critical role in cutting and engraving materials such as metals, plastics, and wood. According to a market research report by Mordor Intelligence, the global laser cutting market is projected to reach USD 6.3 billion by 2026, driven by the increasing demand for high-quality and efficient cutting processes. This technology allows manufacturers to achieve intricate designs with minimal material waste, significantly improving production timelines and lowering costs.

In the healthcare sector, box laser technology is utilized for various applications, including surgical procedures and medical device manufacturing. A report from Research and Markets highlights that the medical laser market is expected to expand at a CAGR of over 15% from 2021 to 2028. The precision of box lasers not only enhances the accuracy of surgical interventions but also ensures a minimally invasive approach, reducing recovery times for patients. Moreover, box lasers are instrumental in the development of advanced medical devices, where precision and reliability are paramount.

Additionally, the automotive industry leverages box laser technology for tasks such as welding, cutting, and marking components. With increasing automation, the demand for high-performance laser systems is on the rise. A study by Grand View Research anticipates that the automotive laser market will grow significantly, highlighting the pivotal role of box lasers in improving production efficiency and product quality. This technology facilitates rapid prototyping and flexible manufacturing, keeping pace with the industry's shift towards customization and sustainable practices.

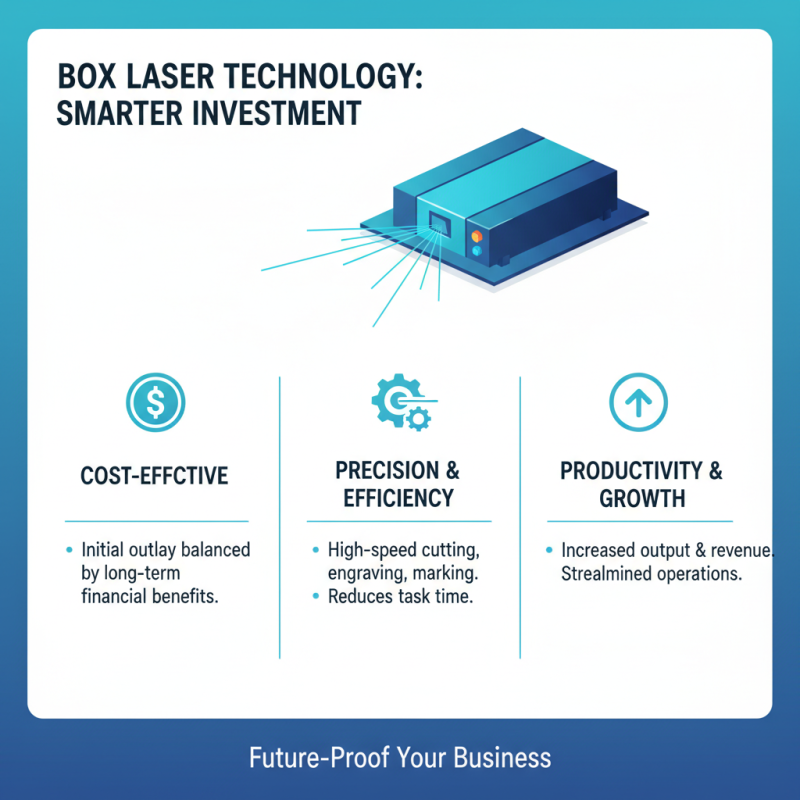

Investing in box laser technology presents a cost-effective solution for businesses seeking precision and efficiency in their operations. The initial outlay for acquiring box laser systems may seem substantial; however, the long-term financial benefits typically outweigh the upfront costs. These systems are designed for high-speed operations, reducing the time needed for tasks like cutting, engraving, and marking materials. As a result, businesses can increase their productivity, leading to higher output and potential revenue growth.

Moreover, box laser systems require lower maintenance compared to traditional machinery, translating to further savings over time. The durability of laser technology minimizes the risk of breakdowns and the need for frequent repairs, allowing companies to allocate resources that would otherwise go to maintenance back into their core activities. Additionally, the precision of laser work reduces material waste, which not only lowers material costs but also aligns with sustainable business practices, appealing to environmentally conscious consumers. Overall, the cost-effectiveness of box laser systems makes them a strategic investment for businesses looking to enhance their efficiency while managing operational costs effectively.

When assessing laser technology options for business applications, Box Laser Technology stands out due to its unique design and capabilities that cater specifically to various industrial needs. Unlike traditional laser systems, which may rely on linear configurations, Box Lasers utilize a compact, enclosed structure that enhances safety and efficiency. This configuration allows for high precision in cutting, engraving, and marking materials, making it an ideal choice for businesses seeking versatility without sacrificing quality.

In comparison to other laser technologies, such as CO2 and fiber lasers, Box Lasers offer distinct advantages in terms of operational costs and maintenance. CO2 lasers are known for their effectiveness with non-metal materials, yet they can require more frequent upkeep and have higher energy consumption. Fiber lasers, while excellent for metal applications, can be more expensive to implement and operate. Box Laser Technology bridges the gap by providing a cost-effective solution that performs well across a wider range of materials, making it an advantageous option for businesses looking to maximize their return on investment while maintaining high production standards.

The field of box laser technology is rapidly evolving, driven by ongoing innovations and the increasing demand for versatility and precision across various industries. Recent industry reports project that the global laser technology market is expected to grow significantly, with a compound annual growth rate (CAGR) of over 5% from 2022 to 2027. This growth underscores the rising adoption of laser systems, particularly in sectors such as manufacturing, healthcare, and telecommunications. New advancements in laser power, beam quality, and automation are enabling businesses to enhance productivity while reducing operational costs.

One of the most promising trends in box laser technology is the integration of artificial intelligence and machine learning. According to a research study, implementing these technologies can increase operational efficiency by up to 30%, reducing errors associated with manual processes. Additionally, the development of more compact and energy-efficient laser systems is paving the way for smaller businesses to tap into high-precision applications, previously accessible only to larger industries. These innovations not only expand the functionality of box lasers but also make them more accessible to diverse market segments, aligning with the growing interest in sustainable and cost-effective manufacturing practices. As companies continue to embrace these technologies, the future of box laser technology looks poised for remarkable transformation.