Choosing the right laser SIC (Silicon Carbide) is crucial for optimizing industrial applications, ensuring efficiency, precision, and scalability in production processes. As industries evolve, the demand for advanced materials like laser SIC has increased, providing significant advantages in thermal conductivity, hardness, and electrical efficiency. This introduction guides you through the essential factors to consider when selecting laser SIC for various applications in sectors such as manufacturing, electronics, and energy.

In the contemporary landscape, where technology is intertwined with industrial operations, understanding the specifics of laser SIC can lead to transformative outcomes. Factors such as performance characteristics, compatibility with existing systems, and the environmental impact of using laser SIC must be scrutinized. By making informed decisions based on these considerations, companies can enhance their operational capabilities and stay competitive in a fast-paced market. Through this guide, we aim to elucidate the valuable insights that will assist you in choosing the right laser SIC tailored to meet your unique industrial needs.

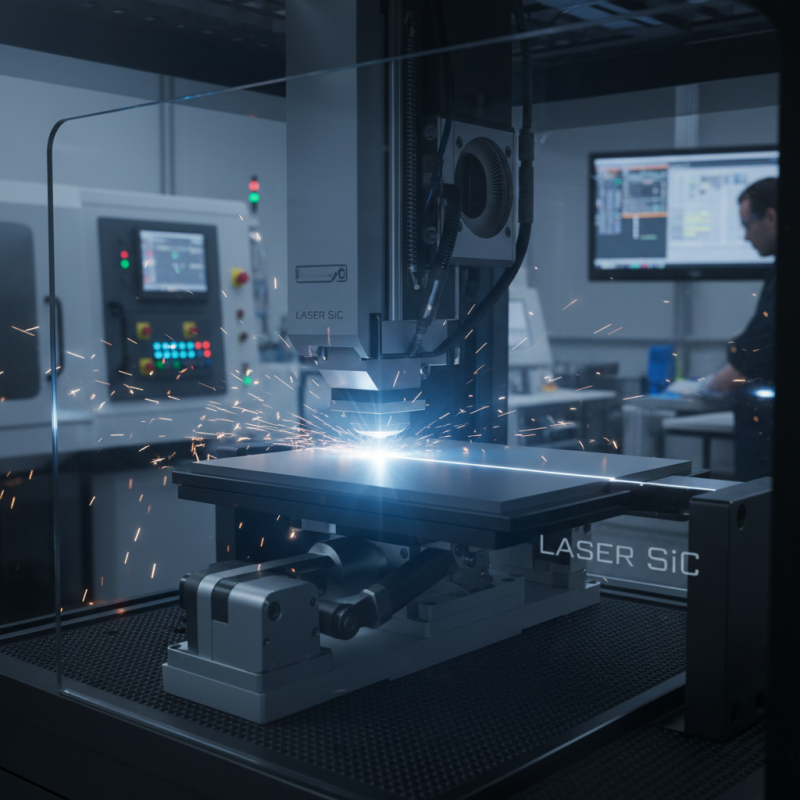

Laser SIC, or Laser-based Silicon-Carbide systems, has become increasingly significant in various industrial applications due to their efficiency and precision. Understanding the fundamentals of Laser SIC is essential, as it influences production quality and operational costs. Laser SIC technology is primarily used in cutting, welding, and engraving processes, offering exceptional material processing capabilities. Its ability to deliver concentrated energy allows for clean cuts and reduced thermal impact on surrounding materials, which is critical in industries that require high precision.

When choosing the right Laser SIC for your applications, consider the specific needs of your operations. One key tip is to evaluate the types of materials you will be working with, as different configurations and power outputs cater to various materials, such as metals or ceramics. Another important aspect is the scalability of the technology; ensure that the system can grow alongside your production demands. Lastly, consider the level of support and maintenance provided, as proper upkeep is essential for maintaining peak performance in any industrial setup.

Investing in Laser SIC technology is not just about the equipment itself; it involves understanding how it fits into your broader operational framework. Engaging with experts and conducting thorough research can provide insights into the latest advancements and practices, enhancing efficiency and productivity across your manufacturing processes.

Identifying the specific industrial applications for Laser SIC (Silicon Carbide) is crucial in selecting the right type for your operations. Different industries, such as automotive, aerospace, and electronics, have unique requirements that influence the choice of a laser SIC. For instance, the automotive sector often demands lasers that can handle high-speed cutting and precision drilling for components like engine parts and fuel systems. Understanding these needs allows businesses to align their laser technology with production goals, ensuring better efficiency and quality.

Moreover, evaluating the material characteristics is essential. Some applications may involve materials requiring high thermal conductivity or specific optical properties, necessitating a tailored laser SIC configuration. Additionally, considering the operational environment is vital; for example, facilities exposed to dust and debris may need robust, sealed laser systems to maintain performance. By thoroughly analyzing these factors and the intended uses, industries can optimize their laser solutions, ultimately leading to enhanced productivity and reduced downtime.

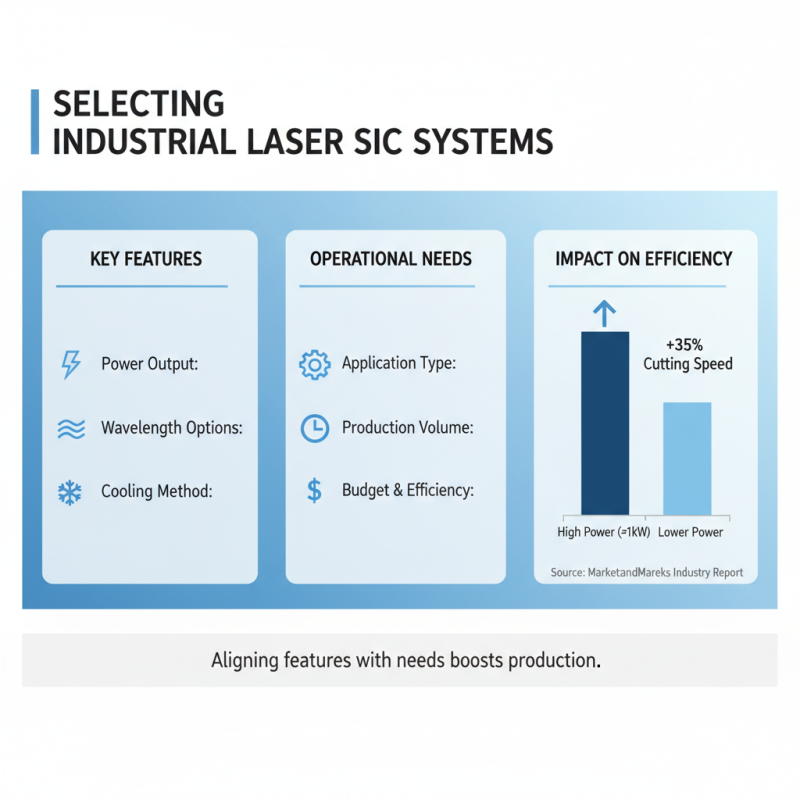

When selecting the right Laser SIC (Silicon Carbide) system for industrial applications, it’s essential to evaluate key features that align with your operational needs. Different laser SIC systems offer varying power outputs, wavelength options, and cooling methods. A recent industry report by MarketsandMarkets indicates that the efficiency of laser systems can significantly impact production rates; for instance, systems with higher power outputs (greater than 1 kW) can enhance cutting speeds by up to 35% compared to lower-powered models.

In addition to power, consider the wavelength of the laser, as it determines the materials that can be effectively processed. According to a study from Research and Markets, the compatibility of specific wavelengths with various materials increases productivity in sectors such as automotive and electronics manufacturing. Furthermore, the cooling mechanism employed—be it air-cooled or water-cooled—can affect maintenance needs and operational costs. Choose systems with efficient cooling solutions for prolonged use and reduced downtime.

**Tips:**

- Analyze the specific materials you will be processing and match them with the laser’s wavelength capabilities.

- Prioritize systems with user-friendly interfaces to simplify operator training and minimize human error.

- Regularly review your system’s efficiency metrics to ensure optimal functioning and to make adjustments as necessary.

When selecting a Laser SIC (Silicon Carbide) for industrial applications, the emphasis on cost-effectiveness and efficiency is paramount. A thorough comparison of different Laser SIC options reveals that not all models provide the same return on investment. Factors such as initial purchase price, operating costs, and maintenance requirements must be carefully evaluated. Lower-cost systems may seem attractive upfront but can incur higher operational expenses due to energy consumption and greater wear over time, resulting in higher overall costs.

Efficiency is another critical component to consider when evaluating Laser SIC technologies. The ability to maintain high-performance levels while consuming less power not only supports sustainability initiatives but also contributes to a reduction in operational expenses. Efficient systems can enhance productivity by minimizing downtime and prolonging the lifespan of components. Therefore, conducting a comprehensive analysis that balances both cost and performance metrics is essential for making an informed choice that aligns with specific industrial needs. Such assessments ensure optimized production processes that ultimately lead to better profitability.

This chart compares the cost-effectiveness and efficiency of various Laser Silicon Carbide (SIC) options for industrial applications. The data represents hypothetical values that demonstrate the relative performance of each laser type.

When selecting a Laser SIC solution for industrial applications, assessing the reliability of suppliers is paramount. A trustworthy supplier not only provides high-quality products but also ensures timely delivery and consistent support throughout the product lifecycle. It’s essential to evaluate suppliers based on their reputation in the industry, customer reviews, and their history of fulfilling client commitments. Engaging with existing customers can offer valuable insights into the supplier’s operational reliability and after-sales service.

Furthermore, the level of support provided by the supplier can significantly impact the effectiveness of the Laser SIC systems in industrial settings. Consider suppliers that offer comprehensive technical support, training programs, and responsive customer service. This ensures that your team is well-equipped to handle any challenges that may arise during installation or operation. A proactive supplier will also provide updates on advancements in technology and maintenance tips, which can enhance the performance of your Laser SIC system and ultimately contribute to the productivity and efficiency of your operations.

| Supplier Name | Reliability Rating (1-5) | Technical Support Availability | Warranty Period | Response Time (Hours) |

|---|---|---|---|---|

| Supplier A | 4 | 24/7 | 2 Years | 2 |

| Supplier B | 5 | Business Hours | 3 Years | 4 |

| Supplier C | 3 | 24/7 | 1 Year | 6 |

| Supplier D | 4 | Business Hours | 5 Years | 3 |

| Supplier E | 5 | 24/7 | 4 Years | 1 |