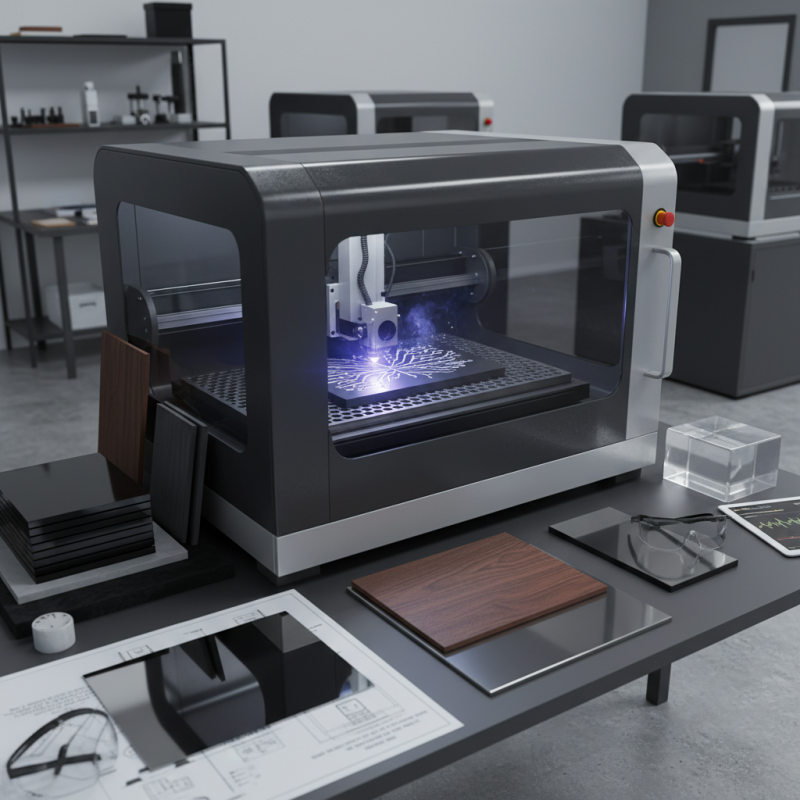

Choosing the right SIC laser for your engraving projects is a pivotal step in ensuring precision, efficiency, and the overall quality of your work. With a multitude of options available in the market, it can be daunting for both beginners and seasoned professionals to navigate through the various features and specifications of SIC lasers. Understanding the distinct attributes of SIC lasers, including their power output, speed, and engraving capabilities, is essential in making an informed decision that aligns with your specific project needs.

Moreover, the material you plan to engrave plays a significant role in your choice of SIC laser. Different materials respond uniquely to laser engraving, and selecting a laser with the appropriate wavelength can enhance the fine details and overall finish of your designs. As technology continues to evolve, the functionality and versatility of SIC lasers improve, offering users innovative solutions for their engraving tasks. Whether your focus is on intricate designs or bulk processing, knowing how to evaluate and choose the right SIC laser will empower you to achieve remarkable results in your engraving projects.

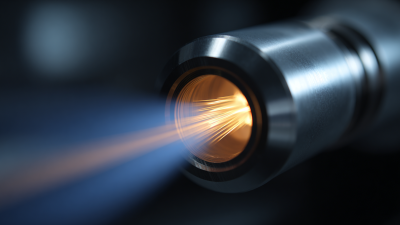

When it comes to engraving, selecting the right SIC laser is crucial for achieving desired results. There are several types of SIC lasers available, each designed with specific features that cater to various engraving needs. CO2 lasers are popular for their ability to engrave on a wide range of materials, such as wood, acrylic, and glass. They provide a smooth finish and are particularly effective for creating intricate designs, making them a favorite among artisans and hobbyists.

Another type is the fiber laser, which excels in marking and engraving on metals and other hard surfaces. Fiber lasers have a longer lifespan and higher efficiency compared to their CO2 counterparts. They are ideal for industrial applications where speed and precision are paramount. Additionally, pulsed and continuous wave lasers are options to consider, with pulsed lasers offering high peak power for deep engraving, while continuous wave lasers provide a more consistent engraving speed and energy output.

Understanding the characteristics of these different types of SIC lasers can help in determining which one suits your specific engraving project. Factors such as the materials you intend to work with, the complexity of designs, and the scale of production should all influence your choice, ensuring that you select the most effective laser for your engraving needs.

When selecting a SIC laser for your engraving projects, several key factors should be carefully considered to ensure optimal results. First and foremost, the power output of the laser is crucial. Typically, higher wattage equates to faster engraving speeds and the ability to work with a wider range of materials. According to industry reports, lasers with an output of 30 to 50 watts are ideal for most engraving applications, allowing for precision and efficiency on various substrates such as wood, glass, and plastics.

Another important aspect to consider is the precision and engraving depth required for your project. Different laser systems offer varied resolution levels, measured in DPI (dots per inch). A laser with 1200 DPI can provide detailed engravings ideal for intricate designs, whereas a 300 DPI laser may suffice for simpler work. Therefore, identifying the level of detail needed in your projects is essential in choosing the right machine.

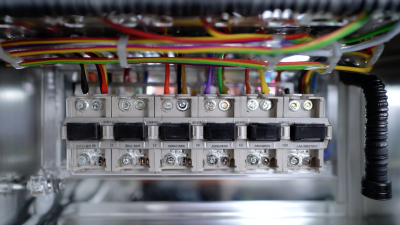

Tips: When evaluating SIC lasers, don’t forget to assess their cooling systems. Efficient cooling can significantly extend the lifespan of your laser and improve performance continuity. Additionally, consider the software compatibility with your existing design tools. Proper integration can enhance your workflow and enable seamless project management. Always consult with professionals or refer to reliable industry data before making your final choice to ensure your investment aligns with your project demands.

| Factors | Description | Example Values |

|---|---|---|

| Laser Power | Determines the speed and depth of engraving. | 20W, 50W, 100W |

| Engraving Speed | The rate at which the laser moves during engraving. | 200 mm/s, 500 mm/s |

| Material Compatibility | Types of materials the laser can engrave effectively. | Wood, Acrylic, Glass, Metal |

| Cooling System | Method used for temperature management during operation. | Air-Cooled, Water-Cooled |

| Software Compatibility | Software programs supported for design and control. | CorelDRAW, AutoCAD |

| Maintenance Requirements | Frequency and types of maintenance needed for optimal performance. | Quarterly Cleaning, Annual Calibration |

When selecting a SIC laser for engraving projects, evaluating power and speed specifications is crucial for achieving outstanding results. Power, measured in watts, directly influences the laser's ability to engrave various materials. Higher wattage allows for deeper engravings and efficient operations on denser materials such as metal and thick wood. However, excessive power may cause unwanted burning or melting, particularly on delicate substrates. Therefore, it's essential to match the laser's power rating according to the specific material and desired engraving depth to ensure quality outcomes.

Speed also plays a significant role in the engraving process. It determines how quickly the laser can move across the material's surface, affecting both the precision and efficiency of the task. A slower speed generally results in more detailed engravings, allowing the laser to make multiple passes for intricate designs. Conversely, increasing the speed might be beneficial for simpler, less detailed work or when time is of the essence. Striking the right balance between speed and power settings is key to optimizing engraving results, ensuring that the project meets both aesthetic and functional requirements.

When selecting a SIC laser for engraving projects, software compatibility and user-friendly features are crucial factors that can significantly impact the overall efficiency and effectiveness of your work. According to a recent industry report, over 60% of users cite software integration as a top priority when choosing laser engraving systems. Ensuring that the laser's software is compatible with popular graphic design applications like Adobe Illustrator and CorelDRAW can streamline the design process, allowing for seamless transitions from digital artwork to tangible products.

Furthermore, user-friendly features such as intuitive interfaces and customizable settings play a critical role in the learning curve associated with laser engraving technology. A survey conducted by the Laser Institute of America highlights that nearly 75% of novice users prefer systems with straightforward controls and detailed instructional resources. This preference underscores the importance of selecting a SIC laser that not only boasts advanced capabilities but also provides an accessible user experience. By focusing on these aspects, engravers can enhance their productivity and creativity, while also minimizing potential frustrations during their projects.

When selecting the right SIC laser for your engraving projects, budget considerations play a crucial role. According to a report from Research and Markets, the global laser engraving market is expected to reach USD 4.3 billion by 2026, with a compound annual growth rate (CAGR) of 5.6%. This robust growth indicates a significant investment opportunity; however, budget constraints often challenge individuals and businesses alike. It's essential to assess your project's specific needs, as prices for SIC lasers can vary widely based on their capabilities, power, and additional features.

To determine the right budget, it is important to evaluate the cost-effectiveness of an investment in a SIC laser system. A 2021 study from the Laser Institute of America noted that entry-level models typically range from USD 3,000 to USD 10,000, while advanced systems can exceed USD 20,000. Evaluating not just the upfront cost but also the operational costs, such as maintenance and consumables, is essential. A well-chosen laser can significantly enhance productivity and reduce the time spent on projects, ultimately delivering a higher return on investment. This careful financial planning will help ensure that the selected SIC laser aligns with both immediate engraving needs and long-term business objectives.