Machine marquage micro percussion has rapidly gained recognition in various industries as a highly effective method for permanent marking on a diverse range of materials. As the demand for precise and durable labeling continues to grow, reports indicate that the global marking systems market is anticipated to reach approximately $4 billion by 2026, with machine micro-percussion marking playing a pivotal role in this upward trend. This technique is favored for its ability to produce high-quality, intricate designs without compromising the integrity of the substrate, making it ideal for applications in automotive, aerospace, and medical device manufacturing.

Moreover, advancements in technology have enhanced the efficiency and accuracy of machine marquage micro percussion, enabling manufacturers to meet stringent quality standards and regulations. A recent study highlighted that over 70% of companies utilizing this marking method reported increased production rates and reduced waste, demonstrating its impact on operational efficiency. As industries realize the benefits of adopting innovative marking solutions, understanding the best practices for implementing effective machine micro-percussion marking techniques becomes crucial for achieving optimal results. This article will delve into the top ten tips to enhance your marking processes, ensuring precision and reliability in your production lines.

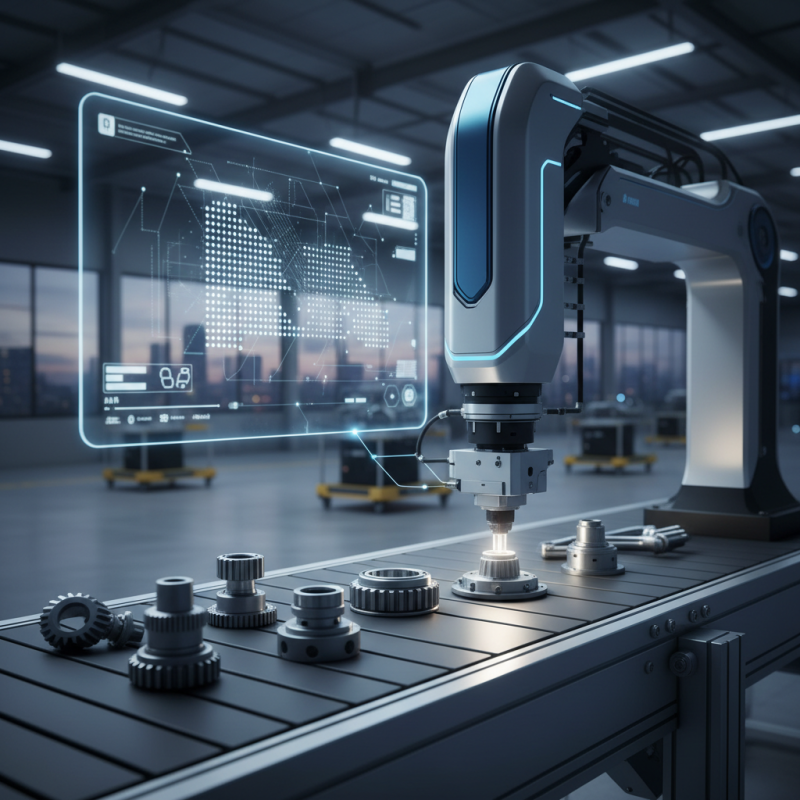

Machine micro-percussion marking is an innovative technique utilized in various industries for precise and durable marking. This process involves creating fine, high-contrast markings on a variety of materials using a series of rapid impacts from a specialized marking tool. Understanding this technique is crucial for optimizing its application, ensuring not only efficiency but also the quality of the output. By comprehending the principles behind micro-percussion marking, operators can better control factors such as impact frequency, depth of marking, and material compatibility, leading to improved results across different projects.

To achieve effective micro-percussion markings, consider the following tips. First, always select the appropriate settings based on the material being marked. Different materials respond uniquely to the impact force and frequency, so adjusting these parameters is essential for avoiding damage while achieving clarity. Another important aspect is maintaining your marking equipment. Regularly inspect and clean the tool to prevent build-up that could affect performance or lead to imprecise markings. Lastly, practice proper alignment of the marking head and the workpiece. Ensuring that both are correctly positioned will minimize the risk of errors and enhance marking accuracy.

By focusing on these fundamental aspects, users can maximize the potential of machine micro-percussion marking techniques, leading to enhanced productivity and quality in their marking applications.

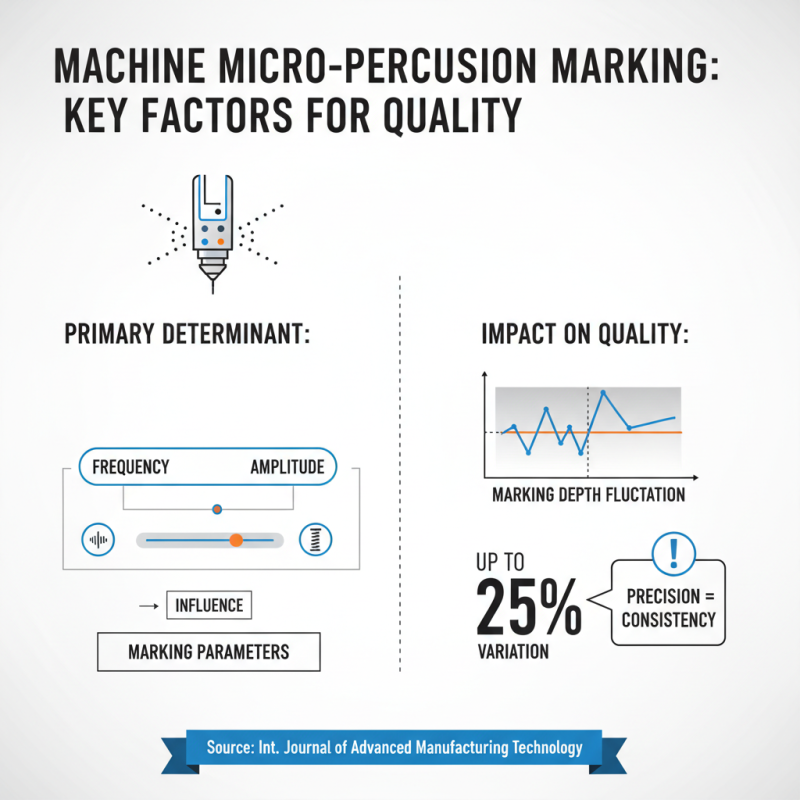

The quality and precision of machine micro-percussion marking techniques are influenced by several key factors that play a crucial role in achieving optimal results. One of the primary determinants is the selection of the marking parameters, including the frequency and amplitude of the marking head. According to a report published by the International Journal of Advanced Manufacturing Technology, variations in these parameters can result in a marking depth fluctuation of up to 25%, highlighting the importance of precise calibration for maintaining consistency and quality in the markings produced.

Another significant factor is the type of material being marked. Different materials react uniquely to micro-percussion marking processes, affecting the clarity and durability of the markings. For instance, metals like aluminum and titanium exhibit varying levels of hardness which can influence the marking effectiveness. A study by the Journal of Manufacturing Processes indicated that using optimized marking techniques for different materials could enhance marking contrast by nearly 30%, significantly improving readability and aesthetic appeal. This underscores the necessity of conducting material-specific assessments to ensure that the marking process is adjusted accordingly, thereby maximizing both precision and quality.

Lastly, environmental conditions during the marking process, such as temperature and humidity, can also impact the outcome. Research from the American Society of Mechanical Engineers suggests that maintaining controlled conditions can reduce variability in marking outcomes, with studies showing that fluctuations in humidity levels can alter the material properties, leading to inconsistent results. Therefore, understanding these key factors is essential for professionals looking to enhance the quality and precision of their machine micro-percussion marking techniques.

Micro-percussion marking is a precision technique widely used in various industries for engraving identification marks, barcodes, or other important information onto metal, plastics, and ceramics. To achieve optimal results, investing in the right essential equipment is crucial. Operators must consider machines that offer precision, reliability, and versatility. According to a report by MarketsandMarkets, the global market for micro-percussion marking machines is projected to grow substantially, reaching approximately $450 million by 2025, highlighting the increasing demand for efficient marking solutions.

The cornerstone of micro-percussion marking effectiveness lies in the machine's capability to produce high-frequency impacts with minimal vibration. This precision is often achieved through the integration of advanced software that allows for control over the marking parameters. Equipment that features adjustable marking depth, speed, and frequency provides the flexibility needed across various materials and applications. Additionally, considering features such as a user-friendly interface and adaptability to different production environments can enhance the overall productivity and quality of marking processes. The combination of robust technical specifications and proper training can significantly improve the efficiency of micro-percussion marking in any industrial setting.

| Tip Number | Tip Description | Essential Equipment | Advantages |

|---|---|---|---|

| 1 | Choose the right material for marking. | High-quality micro-percussion machine. | Ensures durability and effectiveness of marks. |

| 2 | Optimize marking speed for efficiency. | Variable speed controllers. | Increases throughput without sacrificing quality. |

| 3 | Maintain equipment regularly. | Routine maintenance tools. | Prevents breakdowns and extends equipment lifespan. |

| 4 | Adjusting marking depth appropriately. | Depth control settings. | Minimizes material loss and enhances visibility. |

| 5 | Ensure a stable work surface. | Anti-vibration mounts. | Improves marking accuracy and consistency. |

| 6 | Utilize proper programming techniques. | Advanced software for programming. | Enhances customization and precision of marks. |

| 7 | Train operators thoroughly. | Comprehensive training programs. | Reduces mistakes and enhances productivity. |

| 8 | Test marks for quality assurance. | Measurement tools for verification. | Ensures compliance with standards and durability. |

| 9 | Store equipment properly after use. | Climate-controlled storage. | Prevents damage from environmental factors. |

| 10 | Stay updated with latest technologies. | Industry publications and webinars. | Enhances competitive edge and innovation. |

Micro-percussion marking is a precise and efficient method used in various industries for labeling and identification. To implement this technique effectively, it’s essential to follow a structured process. Begin by selecting the right equipment that fits your specific marking needs. Ensure that the machine you choose is compatible with the materials you will be working on, whether it’s metals, plastics, or composites. Setting the machine parameters correctly, such as pressure and frequency, is crucial for achieving clear and durable marks.

Once your equipment is ready, prepare the surface of the item to be marked. Clean the area to remove any contaminants that may affect the clarity of the mark. Position the item securely in the marking machine to prevent any movement during the marking process, which can lead to smudging or misalignment. Execute a test mark on a similar material to fine-tune the settings before proceeding with the final marking. After achieving satisfactory results, conduct the marking process, ensuring a steady pace and consistent pressure throughout. Finally, inspect the marks for quality and durability, making adjustments to your technique if necessary.

This bar chart illustrates the effectiveness of various micro-percussion marking techniques based on several key dimensions including speed, precision, durability, versatility, and cost. The data points represent the performance metrics in each category.

Micro-percussion marking techniques are essential in various manufacturing processes, offering precision and durability for item identification. However, several challenges can arise during implementation. One common challenge is the inconsistent depth of marks, which can affect readability and effectiveness. According to a report by the Industrial Marking Association, nearly 30% of manufacturers encounter issues with inconsistent marking depths, often due to variations in material hardness or equipment settings. To overcome this, it is crucial to conduct material-specific calibrations and regularly maintain the marking equipment to ensure consistent performance.

Another challenge in micro-percussion marking is the potential for excessive material stress, leading to defects in the product. Research indicates that improper marking techniques can induce micro-cracks in sensitive materials, which can compromise the structural integrity of components. To address this issue, implementing advanced marking strategies such as optimized force settings and adjusting the marking speed can minimize stress while still achieving clear, legible marks. Industry professionals suggest that utilizing simulation software to model the marking process can significantly aid in identifying potential issues before physical implementation, leading to improved results and overall production efficiency.