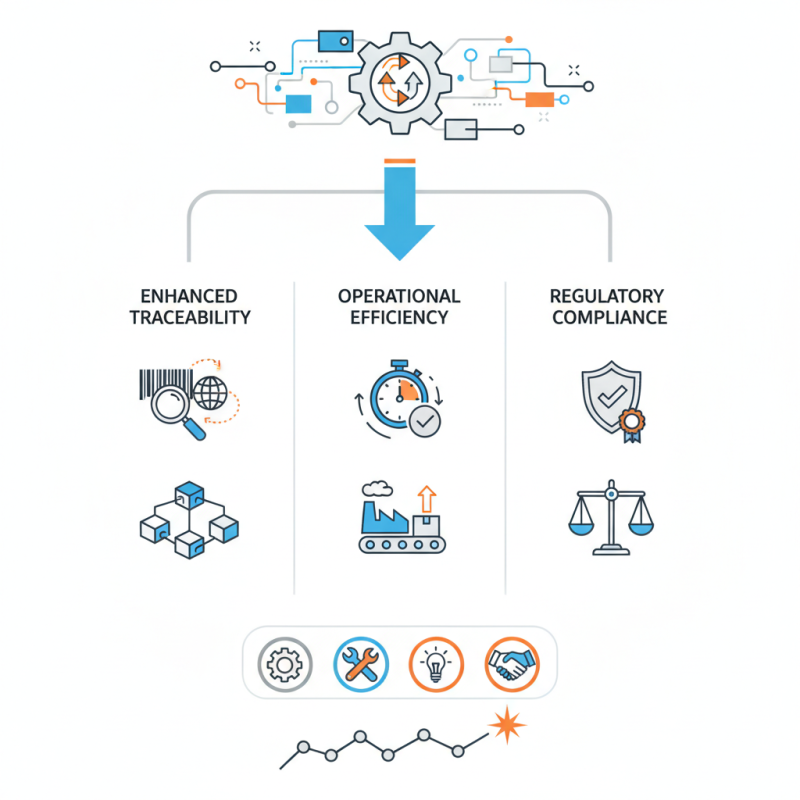

In today's competitive manufacturing landscape, the implementation of advanced marking technologies is crucial for businesses aiming to enhance their product traceability and brand integrity. One such innovative solution is the Sic Marking P123, a state-of-the-art marking system designed to meet diverse industrial needs. As noted by industry expert John Smith, "The Sic Marking P123 is not just a marking solution; it is a pathway to efficiency and compliance in a rapidly evolving market."

The effective integration of the Sic Marking P123 into business operations can yield significant benefits, from improved operational workflows to a greater ability to meet regulatory requirements. By adopting this cutting-edge marking technology, companies can ensure that their products not only stand out but also remain compliant with industry standards. In this article, we will explore the key steps and best practices for implementing Sic Marking P123, offering insights that can help businesses harness its full potential for enhanced performance and customer satisfaction.

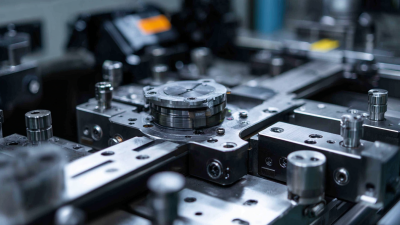

Sic Marking P123 technology is revolutionizing the way businesses approach their marking and identification needs. This advanced laser marking system offers unparalleled precision and durability, which are essential in today’s competitive market. According to a recent report by MarketsandMarkets, the global laser marking market is projected to grow from $3.3 billion in 2020 to $5.3 billion by 2025, indicating a significant shift towards high-tech solutions like Sic Marking P123. Its ability to produce high-quality, permanent marks on various materials makes it suitable for industries such as automotive, aerospace, and electronics, where traceability and compliance with regulations are paramount.

One of the key features of the Sic Marking P123 is its versatility, capable of processing materials ranging from metals to plastics. This adaptability is crucial, as more industries seek to integrate marking solutions that ensure brand integrity and product safety. A survey conducted by the Marking & Coding Association revealed that 65% of manufacturers prioritize equipment with reduced downtime and maintenance needs, which Sic Marking P123 satisfies with its reliable performance and user-friendly interface. Additionally, the system's ability to integrate with IoT technologies positions it favorably within the trends of Industry 4.0, allowing for real-time data tracking and enhanced operational efficiency.

When considering the implementation of Sic Marking P123 solutions, the first step is assessing your specific business needs. Conducting a thorough analysis of your current marking requirements will help identify gaps and opportunities for improvement. Consider factors such as production volume, types of materials being marked, and any regulatory compliance requirements. Engaging with key stakeholders in your organization can provide insights into how P123 solutions can enhance efficiency and meet operational goals.

**Tips:** One effective strategy is to map out your existing workflow to visualize where marking plays a critical role. This will help in pinpointing areas where automation could save time and reduce errors. Additionally, consider scheduling a trial period for the P123 solution to assess its compatibility with your processes and to gather valuable feedback from your team.

Furthermore, evaluate the scalability of the P123 marking system. Your business needs may evolve, and it is essential that the solutions you choose adapt accordingly. Look into customizable options that can cater to growing demands or changing regulatory requirements. Keeping future needs in mind will help ensure that your investment is both beneficial and sustainable in the long run.

Integrating Sic Marking P123 into your business operations requires a structured approach to ensure efficiency and effectiveness. According to a recent industry report by MarketsandMarkets, companies that systematically implement advanced marking solutions see a 15% increase in traceability and a 20% reduction in operational errors. To start with, businesses should conduct an operational assessment to identify specific needs and how the P123 can meet them. This step not only aligns the technology with business objectives but also enhances employee engagement by involving them in the integration process.

Once the assessment is complete, the next phase involves a phased training program for staff. A study by the Manufacturing Institute indicates that organizations that invest in comprehensive employee training programs have a 30% higher satisfaction rate among workers, which in turn correlates with improved productivity. During the training, employees should focus on understanding the features of the P123, including its customizable marking capabilities and connectivity with other systems. After training, implementing a pilot program can help fine-tune the integration, allowing for adjustments before a full rollout. By following these steps, businesses can not only enhance their operational efficiency but also maximize the benefits of the Sic Marking P123.

| Step | Description | Duration | Resources Needed | Expected Outcome |

|---|---|---|---|---|

| 1 | Define Business Needs | 1 Week | Internal Documentation | Clear understanding of marking requirements |

| 2 | Select Equipment | 2 Weeks | Market Research, Supplier Quotes | Procured equipment suitable for needs |

| 3 | Install and Configure | 1 Week | Installation Tools, Technical Assist | Operational marking setup |

| 4 | Employee Training | 2 Weeks | Training Materials, Expert Trainers | Skilled operators for proper use |

| 5 | Pilot Testing | 3 Weeks | Test Products, Monitoring Tools | Assess functionality and adjust as needed |

| 6 | Full Implementation | 2 Weeks | Workforce, Production Lines | Sustainable marking integrated into operations |

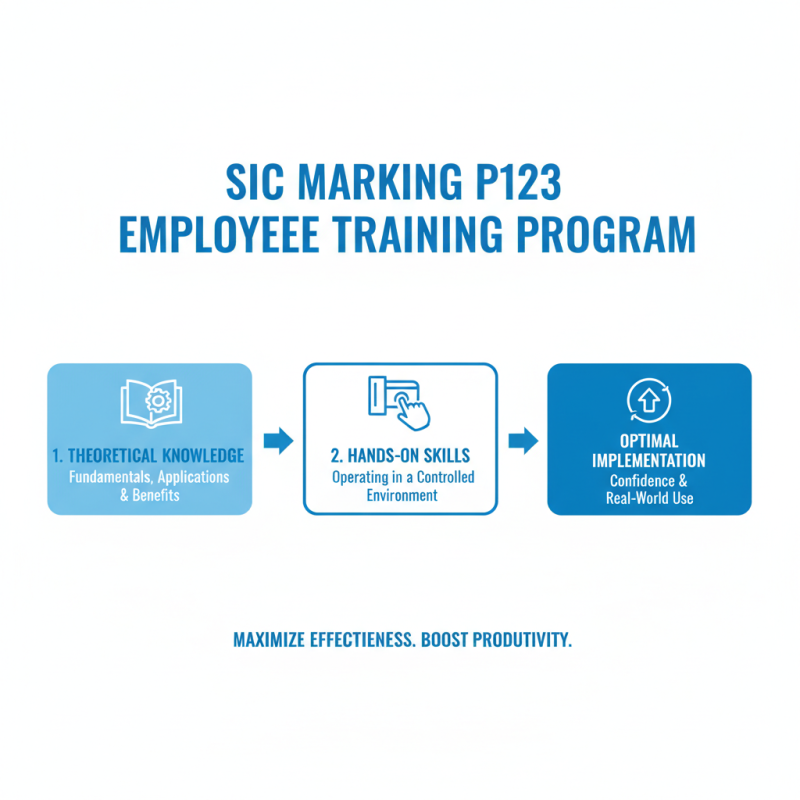

Training employees on Sic Marking P123 is crucial for maximizing its effectiveness within your business. To ensure optimal use, it's essential to develop a structured training program that incorporates theoretical knowledge as well as practical skills. Employees should first be acquainted with the fundamentals of Sic Marking P123, including its applications and advantages. Following this, hands-on training sessions can help employees practice operating the system in a controlled environment, allowing them to gain confidence before implementing it in real-world scenarios.

Incorporating innovative training resources can enhance the learning experience. Utilizing online modules, videos, and interactive workshops can cater to various learning styles, ensuring that every employee can engage with the material effectively. Just as recent advancements in technology training underline the importance of adapting to new tools, so too must businesses embrace comprehensive training strategies for their marking systems. This approach not only improves employee proficiency but also contributes to a more efficient workflow and better overall performance in utilizing Sic Marking P123 for business needs.

Monitoring and evaluating the success of the Sic Marking P123 implementation is crucial for ensuring that your business objectives are met. Establishing clear performance metrics at the outset can help track progress and identify areas that need adjustment. Metrics could include production efficiency, product traceability improvements, and cost savings. Regularly reviewing these metrics allows for timely interventions, ensuring that the implementation aligns with your business goals.

Tips: One effective strategy is to set up quarterly reviews where your team analyzes the data against the initial benchmarks. This not only keeps everyone accountable but also fosters a culture of continuous improvement. Additionally, consider using feedback from employees who interact with the marking system daily, as their insights can provide valuable information about any operational hiccups.

Another key aspect of monitoring is maintaining open lines of communication with all stakeholders involved in the implementation process. Encourage discussions about any challenges faced and celebrate successes, no matter how small. This collective approach can enhance team morale and drive commitment towards the successful integration of the P123 technology, ultimately leading to a robust evaluation of its success.

This bar chart shows the productivity over four quarters following the implementation of Sic Marking P123. The data indicates a steady increase in units produced, highlighting the effectiveness of the implementation strategy.