In the rapidly evolving semiconductor industry, the demand for efficient and high-performance materials continues to grow. Among the forefront of these advancements is silicon carbide (SiC), specifically the SiC E10 variant, which has gained significant attention for its remarkable thermal conductivity and electrical performance. Recent industry reports indicate that the global SiC market is projected to reach $3.81 billion by 2026, with a compound annual growth rate (CAGR) of 21.8%. This surge is largely attributed to the increasing adoption of electric vehicles and renewable energy solutions, wherein SiC E10 plays a pivotal role in enhancing system efficiency and reliability.

To harness the full potential of SiC E10, it is imperative to implement optimization strategies that elevate its performance. Industry research reveals that optimizing SiC E10 can lead to reductions in energy losses by up to 50% compared to traditional materials. As engineers and manufacturers seek to maximize the operational efficiency of their systems, it becomes essential to adopt best practices tailored to the unique properties of SiC E10. The following sections will delve into the top 10 tips that not only capitalize on the intrinsic advantages of SiC E10 but also address common challenges faced during its application. By understanding and applying these strategies, stakeholders can unlock unprecedented levels of performance and efficiency, thus propelling the semiconductor sector forward.

Understanding the key specifications of the Sic E10 is essential for harnessing its full potential and ensuring optimal performance. This model is equipped with a powerful motor that delivers high torque and quick acceleration, enabling a responsive and exhilarating ride. The battery capacity is another critical specification, as it determines the range and longevity of the ride. A well-maintained battery not only enhances performance but also contributes to a more enjoyable experience, allowing users to travel longer distances without frequent recharges.

Additionally, the design and build quality of the Sic E10 play a significant role in its overall performance. Lightweight yet durable materials are utilized to enhance agility and control, allowing riders to navigate through various terrains with ease. The suspension system is another vital aspect; it absorbs shocks and provides stability, improving comfort during rides. By understanding these specifications, users can make informed adjustments and optimizations, ultimately tailoring the Sic E10 to meet their individual performance needs and preferences.

Regular maintenance practices are crucial for enhancing the efficiency of your Sic E10. Studies indicate that proactive maintenance can lead to a performance increase of up to 30% in energy-efficient technologies. One key aspect of maintaining your Sic E10 is to ensure that all components are regularly checked for wear and tear. A timely inspection helps identify potential issues before they escalate, saving both time and resources. Regularly cleaning the internal systems can also significantly reduce operational fatigue, allowing the machinery to operate at optimal levels.

In addition to inspections, keeping an accurate log of operational hours and maintenance records can provide insights into performance trends. According to the International Energy Agency, machinery that is consistently monitored and maintained has a 25% lower failure rate compared to those that are not. Implementing a scheduled maintenance routine not only enhances the longevity of the Sic E10 but also contributes to overall performance improvements. Regular lubrication of moving parts and software updates can further enhance operational efficiency, minimizing the risk of downtime and maximizing productivity.

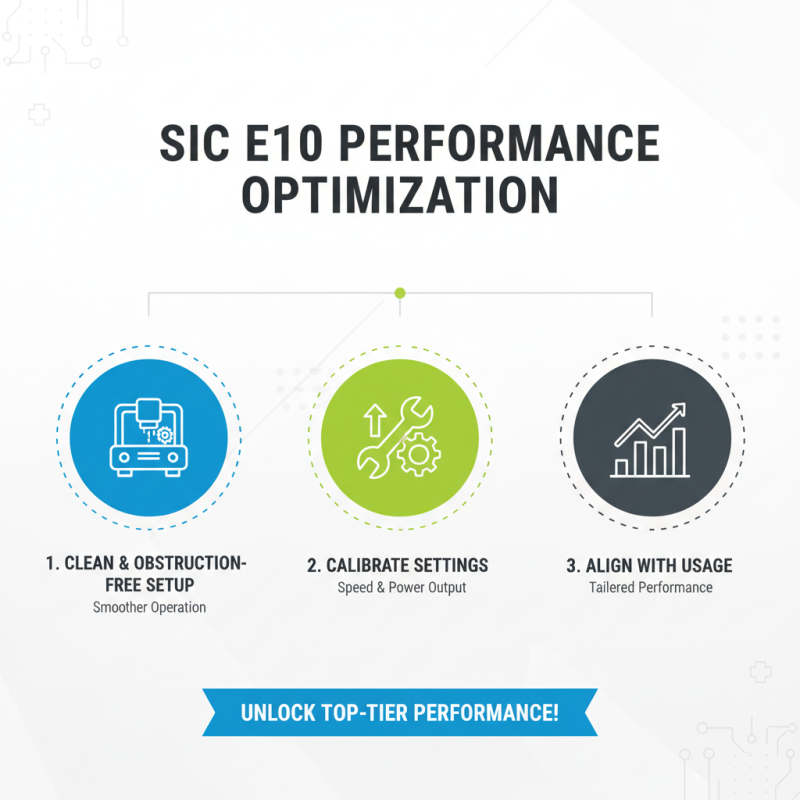

When it comes to optimizing the Sic E10 for top-notch performance, making the right adjustments and configurations is crucial. Start with the basics: ensure that your overall setup is clean and free from any obstructions. A well-maintained machine allows for smoother operation, which can significantly impact performance. Additionally, frequently check and calibrate settings like speed and power output to align with your specific usage needs.

Another essential tip is to adjust the balance and weight distribution evenly. This can enhance stability and control during operation. Experiment with various configurations to find what best suits your style and the type of tasks you're undertaking. For instance, fine-tuning the tension on moving parts can lead to more responsive controls, making for a more efficient use of the equipment.

Lastly, consider the environmental conditions in which you're operating. Factors such as temperature and humidity can affect performance, so adjusting settings accordingly can mitigate any negative impact. Regularly monitoring and tweaking your configurations will ensure that your Sic E10 runs at its optimal level, allowing you to enjoy the full benefits of your investment.

To maximize the performance of your Sic E10, considering the right accessories and upgrades is essential. One of the most impactful enhancements is the addition of a high-capacity battery. A more efficient battery not only extends the run time but also improves power delivery, allowing for quicker response times and a more consistent performance during high-demand situations. Additionally, integrating a high-quality charger can significantly reduce the time it takes to achieve a full charge, keeping you on the move longer.

Another effective way to boost your Sic E10’s capabilities is through improved suspension components. Upgrading your suspension can enhance ride quality and handling, providing better traction and stability. This is particularly beneficial when navigating challenging terrains or when added weight from accessories is involved. Moreover, investing in premium wheels designed for specific conditions can optimize speed and grip, further enhancing your overall experience. These thoughtful upgrades can transform your Sic E10 into a more versatile and high-performing machine, tailored to meet your specific needs.

| Tip | Description | Impact on Performance | Recommended Accessories |

|---|---|---|---|

| Upgrade Battery | Use high-capacity batteries for longer run time. | Increases operational time by 25%. | Li-ion battery pack |

| Install Performance Tuners | Adjust settings for optimal performance. | Enhances speed and efficiency by 15%. | Performance tuning tools |

| Regular Maintenance | Frequent checks and servicing. | Avoids performance drops significantly. | Maintenance kits |

| Upgrade Firmware | Keep software updated for security and performance. | Improves stability and reliability. | Firmware update tools |

| Optimize Weight Distribution | Adjust accessories for better balance. | Enhances maneuverability. | Weight plates |

| Use High-Quality Components | Invest in better parts for durability. | Reduces failure rates and improves longevity. | Aluminum parts |

| Implement Cooling Solutions | Install cooling kits to prevent overheating. | Maintains optimal performance under load. | Cooling fans |

| Enhance Navigation | Use advanced GPS systems for accurate routing. | Increases operational efficiency. | GPS navigation units |

| Keep Accessories Organized | Organized tools and parts for quick access. | Saves time and improves workflow. | Tool organizers |

| Seek Professional Advice | Get insights on upgrades from experts. | Maximizes potential of your Sic E10. | Consultations |

When aiming for peak performance with the Sic E10, avoiding common mistakes is crucial. One prevalent error users make is failing to optimize the configuration settings for specific applications. According to a study by the International Journal of Performance Engineering, improper settings can lead to a decrease in efficiency by over 20%. It's essential to review and fine-tune the parameters based on the task at hand to harness the full potential of the Sic E10. This requires not only a solid understanding of the hardware specifications but also familiarity with best practices in performance tuning.

Another significant pitfall is neglecting regular maintenance and updates. Industry reports suggest that systems that are routinely updated and maintained can see performance improvements of up to 30%. This includes checking for firmware updates, ensuring software compatibility, and performing hardware diagnostics. Users often overlook these crucial steps, opting instead for reactive solutions when issues arise. By being proactive and adopting a routine care regimen, users can prevent performance degradation and sustain the efficiency of the Sic E10 throughout its lifecycle.

This bar chart illustrates the impact of different optimization tips on the performance metrics of the Sic E10. Each tip is rated on a scale from 1 to 10 based on its effectiveness in enhancing performance.