In recent years, the emergence of silicon carbide (SiC) laser technology has revolutionized various sectors of modern industry, offering enhanced efficiency and precision in applications ranging from telecommunications to manufacturing. As industry expert Dr. Emily Carter, a prominent figure in semiconductor research, notes, “SiC lasers represent a paradigm shift in laser technology, combining high power output with remarkable thermal stability.” This remarkable advancement promises not only to streamline existing processes but also to enable innovative applications that were previously deemed unfeasible.

The versatility of SiC lasers is reflected in their growing utilization in multiple domains, including material processing, medical technologies, and even aerospace applications. Their ability to perform under extreme conditions makes them an ideal choice for some of the most demanding industries, facilitating breakthroughs that could lead to significant improvements in performance and cost-effectiveness. As the technology continues to advance, the potential for SiC lasers to foster new innovations remains substantial, positioning them as a key player in the future of industrial technology.

Through an in-depth exploration of SiC laser technology and its wide array of applications, we can gain valuable insights into how this cutting-edge tool is reshaping the landscape of modern industry, ultimately driving progress and efficiency across various sectors.

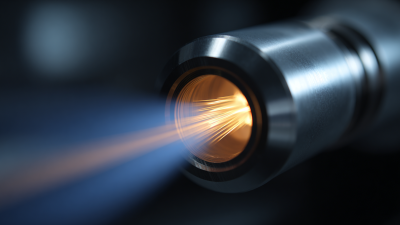

Silicon carbide (SiC) laser technology has emerged as a significant development in the realm of high-performance laser systems, especially in industrial applications. SiC lasers operate based on unique mechanisms that leverage the superior thermal conductivity and wide bandgap properties of silicon carbide. This material enables lasers to achieve higher efficiency and output power while maintaining thermal stability. A report from ResearchAndMarkets indicates that the global SiC laser market is expected to reach $1.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 20.9% from 2020.

The mechanisms involved in SiC laser technology allow for the generation of high-quality laser beams suitable for precision cutting, welding, and other manufacturing processes. The ability of SiC to withstand high temperatures and its resistance to chemical corrosion make it an ideal choice for harsh industrial environments. According to a study published by the International Journal of Advanced Manufacturing Technology, SiC lasers demonstrate significantly lower maintenance costs and longer operational lifespans compared to traditional laser systems, further enhancing their appeal in modern manufacturing sectors. As industries strive for more efficient and reliable technologies, SiC lasers are poised to play a crucial role in applications ranging from automotive to aerospace, ultimately transforming production processes.

| Application Area | Type of SIC Laser | Wavelength (nm) | Power Output (W) | Efficiency (%) |

|---|---|---|---|---|

| Medical Surgery | Solid-State SIC Laser | 980 | 30 | 70 |

| Manufacturing | Fiber-coupled SIC Laser | 1064 | 500 | 85 |

| Metal Cutting | High-Power SIC Laser | 1030 | 3000 | 90 |

| 3D Printing | Diode SIC Laser | 780 | 150 | 75 |

| Telecommunications | Signal SIC Laser | 1550 | 20 | 95 |

Silicon carbide (SiC) lasers are rapidly gaining traction in modern industrial applications due to their remarkable advantages over traditional laser systems. One of the most significant benefits of SiC lasers is their superior thermal conductivity, which allows for efficient heat dissipation. Reports indicate that SiC crystals can withstand temperatures exceeding 600°C, enabling these lasers to operate at higher power levels without compromising performance. This thermal resilience not only extends the life span of the laser system but also enhances reliability, making SiC lasers ideal for demanding environments such as automotive manufacturing and aerospace applications.

Additionally, SiC lasers exhibit improved efficiency and lower operational costs compared to their traditional counterparts. For instance, industry studies show that SiC laser systems can achieve electrical-to-optical conversion efficiencies of over 80%, significantly reducing energy consumption in comparison to conventional laser technologies, which typically offer efficiencies between 25% and 50%. This increased efficiency translates to tangible cost savings for manufacturers, allowing them to allocate resources more effectively. Furthermore, with advancements in SiC fabrication techniques, the scalability of these lasers is becoming more feasible, paving the way for widespread adoption across various industrial sectors.

Silicon carbide (SiC) laser technology has emerged as a game-changer in modern manufacturing processes, revolutionizing a number of industries with its unique properties. This technology offers high efficiency and excellent thermal conductivity, making it ideal for applications such as precision cutting, welding, and engraving. According to a recent report by Research and Markets, the global SiC laser market is expected to grow at a compound annual growth rate (CAGR) of 20.5% by 2027, highlighting its increasing adoption in sectors such as automotive, aerospace, and electronics.

In manufacturing, the versatility of SiC lasers enables fine detail work that traditional technologies often cannot achieve. For instance, their ability to operate at higher temperatures allows for faster processing times and improved overall productivity. A survey by MarketsandMarkets indicates that over 50% of manufacturers are now incorporating advanced laser technologies to enhance their operational efficiency, with SiC lasers being at the forefront of this transition.

Tips: When considering the integration of SiC laser technology, assess the specific requirements of your manufacturing processes. Understanding your material compatibility and desired outcomes can significantly impact your success with SiC lasers. Additionally, continuous employee training on the latest laser techniques can help maximize the effectiveness of this advanced technology in your operations.

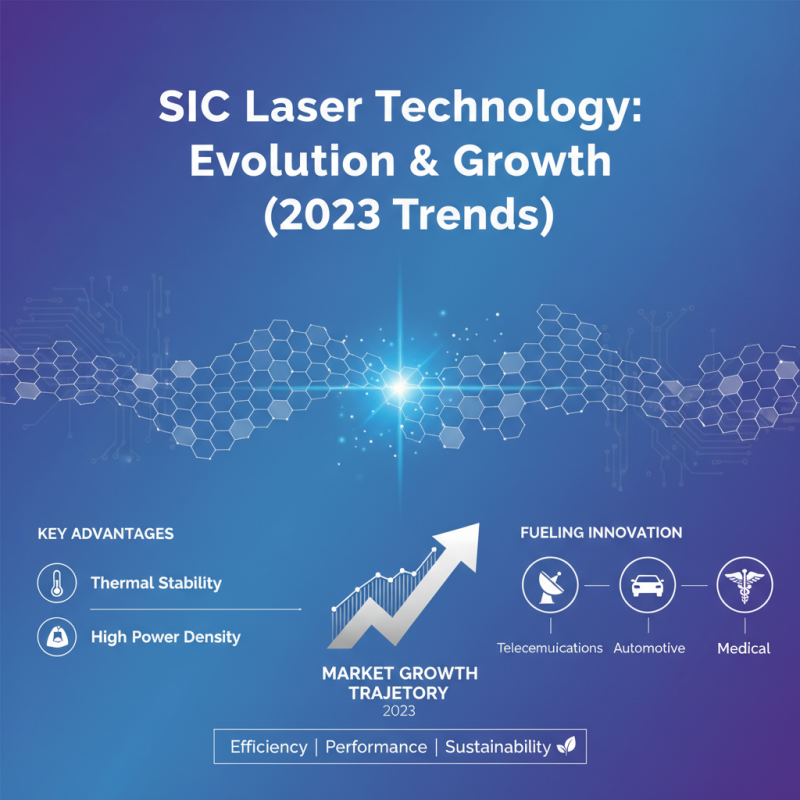

The landscape of SIC (Silicon Carbide) laser technology has been rapidly evolving, reflecting the increasing demand for more efficient and high-performance solutions across various industries. In 2023, market trends indicate a significant growth trajectory, fueled by advancements in semiconductor materials and the rising adoption of SIC lasers in applications such as telecommunications, automotive, and medical sectors. As industries continuously seek to improve production processes and reduce energy consumption, SIC lasers—known for their thermal stability and high power density—stand out as a powerful solution.

Tips: When considering the integration of SIC laser technology into your operations, focus on understanding the specific needs of your application. Assess the advantages that SIC lasers bring, such as reduced heat generation and enhanced precision. This can lead to improved product quality and operational efficiency.

The growth forecast for SIC laser technology in the coming years is robust, driven by innovations in manufacturing processes and the shift towards more sustainable technologies. Emerging trends point towards miniaturization and enhanced functionality, catering to the need for compact and versatile systems. As companies invest in research and development, the potential for SIC lasers expands, positioning them as essential tools in achieving competitive advantage.

Tips: Stay updated on industry developments and networking opportunities to gain insights from peers. Participating in forums or conferences can provide valuable information on the latest technological advancements and market demands.

SIC (Silicon Carbide) laser technology is rapidly gaining traction in various industries due to its remarkable efficiency and exceptional performance. However, the challenges it faces in practical applications cannot be ignored. One significant hurdle is the integration of SIC lasers into existing manufacturing processes. According to a report by MarketsandMarkets, the global SIC market is expected to reach $8.3 billion by 2024, indicating a promising future but also emphasizing the need for adaptable integration solutions.

As SIC laser technology continues to evolve, researchers are focusing on developing higher power outputs and improved thermal management systems. Data from Frost & Sullivan highlights that the laser systems capable of operating at higher temperatures will likely dominate the market by 2025. However, this progress is tempered by the high manufacturing costs associated with SIC materials, which can hinder widespread adoption. Addressing these economic barriers while improving energy efficiency remains a critical challenge for developers and manufacturers.

**Tip:** When considering SIC laser technology for industrial applications, assess the compatibility with your current machinery and the potential for scaling production without excessive costs. Additionally, staying informed on advancements in thermal management can enhance operational efficiency significantly. Continuous investment in R&D will be vital in overcoming these challenges and unlocking the full potential of SIC lasers in modern industrial applications.