In the ever-evolving landscape of manufacturing, innovations in SIC machines are at the forefront of enhancing efficiency and productivity. As industries strive to meet growing demands, the introduction of advanced SIC machine technologies is proving to be a game changer. Experts in the field, such as Dr. Emily Carter, a renowned manufacturing engineer, have emphasized the importance of these innovations: "The evolution of SIC machines is not just about cutting-edge technology; it’s about redefining what efficiency means in manufacturing today."

The year 2023 has seen remarkable advancements in SIC machines, from automation features that streamline processes to smart technology that predicts maintenance needs before they become critical. These innovations empower manufacturers to operate more smoothly and reduce production downtime significantly. As we explore the top ten SIC machine innovations driving efficiency this year, it becomes evident how crucial these advancements are for manufacturers aiming to enhance their competitive edge.

Understanding the impact of SIC machine innovations helps us appreciate the broader context of manufacturing progress. With each technological leap, companies are not only improving their bottom line but also contributing to a sustainable future. The integration of smarter, more efficient SIC machines positions the industry to tackle future challenges head-on, ensuring a resilient manufacturing ecosystem.

The semiconductor industry is undergoing a transformative evolution, particularly with the advancements in Silicon Carbide (SiC) technologies. As manufacturing processes adapt to the Fourth Industrial Revolution, SiC devices are becoming increasingly central to enhancing efficiency and performance. These innovations are not only addressing the growing demand for power electronics but also positioning the industry to meet the challenges of sustainability and energy efficiency.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into manufacturing processes has emerged as a game changer in enhancing operational efficiency. By leveraging vast amounts of data, these technologies enable manufacturers to predict maintenance needs, optimize production schedules, and enhance quality control. AI algorithms can analyze patterns in machinery performance, allowing for predictive analytics that significantly reduce downtime and unexpected failures.

Moreover, Machine Learning applications facilitate real-time decision-making by continually learning from ongoing processes and outcomes. This adaptability leads to smarter resource allocation, reducing waste and ensuring that materials are used more efficiently. By employing AI-driven automation, manufacturers can streamline workflows and reduce manual errors, ultimately speeding up production cycles.

The transformative power of integrating AI and ML signifies a pivotal shift in manufacturing, where efficiency isn't just an objective but an achievable reality facilitated by technology.

The integration of smart automation systems has become a pivotal strategy in manufacturing, particularly in 2023, as companies strive to enhance productivity and efficiency. According to a report by the International Federation of Robotics, global sales of industrial robots are expected to reach 500,000 units annually by 2025, demonstrating a significant shift towards automation. This surge is driven by the need for manufacturers to streamline production processes, reduce labor costs, and improve product quality.

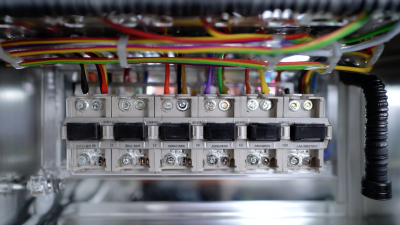

Advanced automation technologies, such as AI-driven analytics and IoT (Internet of Things) connectivity, are playing a crucial role in optimizing manufacturing workflows. For instance, a study by McKinsey indicates that companies that implement smart automation can achieve productivity gains of 20-30% while significantly minimizing downtime. These intelligent systems allow real-time monitoring of production lines, enabling quick adjustments to mitigate inefficiencies. As manufacturers increasingly adopt these innovations, the landscape of production is transforming, leading to more agile and responsive operations that meet the demands of today's fast-paced market.

Advanced automation technologies, such as AI-driven analytics and IoT (Internet of Things) connectivity, are playing a crucial role in optimizing manufacturing workflows. For instance, a study by McKinsey indicates that companies that implement smart automation can achieve productivity gains of 20-30% while significantly minimizing downtime. These intelligent systems allow real-time monitoring of production lines, enabling quick adjustments to mitigate inefficiencies. As manufacturers increasingly adopt these innovations, the landscape of production is transforming, leading to more agile and responsive operations that meet the demands of today's fast-paced market.

In 2023, the push for sustainability in manufacturing has become a core focus, with various innovations in silicon carbide (SiC) technology leading the way. These eco-friendly advancements not only improve efficiency but also significantly reduce energy consumption. According to industry reports, SiC devices can operate at higher temperatures and voltages compared to traditional silicon-based counterparts, resulting in over 30% energy savings in power systems. This capability enhances the overall effectiveness of energy systems while promoting environmental stewardship.

One standout innovation is the personalized capsule machine, which reflects a growing trend towards customization in manufacturing. By utilizing real-time health data and automated production processes, this advanced technology optimizes dosing accuracy and enables on-demand capsule manufacturing. Such innovations underscore the shift towards personalization in various sectors, aiming to meet consumer demands while minimizing waste.

Tips for Manufacturers:

1. Embrace Sustainable Practices: Transitioning to SiC technologies can result in significant energy savings, enhancing your company’s green credentials.

2. Invest in Automation: The adoption of automated and data-driven approaches can streamline operations and offer personalized solutions that cater to changing consumer needs.

3. Stay Informed: Keep an eye on emerging startups in the field that focus on sustainability, as they often lead the way in innovative practices that can benefit established businesses.

Real-time data analytics is reshaping decision-making processes in manufacturing, allowing organizations to harness the power of data to enhance operational efficiency. As Industry 4.0 technologies gain traction, the integration of real-time analytics enabled by the Internet of Things (IoT) has become paramount. By leveraging IoT devices, manufacturers can monitor production lines continuously, providing instant insights into performance and potential bottlenecks. This capability empowers decision-makers to respond swiftly to changes, optimize resource allocation, and ultimately reduce downtime.

Furthermore, advancements in AI and 5G technology play a critical role in maximizing these analytics capabilities. Fast wireless technology facilitates seamless data transfer, enabling real-time processing of vast amounts of information. As a result, manufacturers are able to implement predictive maintenance strategies, significantly lowering costs and improving productivity. The synergy between AI and data analytics paves the way for smarter manufacturing environments, where proactive decision-making becomes the norm, driving innovation and competitiveness in the industry.

| Innovation | Description | Impact on Efficiency | Implementation Time (Months) | ROI (% within 1 Year) |

|---|---|---|---|---|

| Predictive Maintenance | Utilizing data analytics to predict equipment failures before they occur. | Reduces downtime by 20% | 6 | 150% |

| Real-time Monitoring | Continuous tracking of machine performance and product quality. | Improves quality control and reduces waste by 15% | 3 | 120% |

| Supply Chain Integration | Sharing real-time data across suppliers and logistics. | Increases supply chain efficiency by 30% | 12 | 110% |

| Automated Scheduling | AI-driven scheduling that adapts to changes in demand. | Enhances production scheduling by 25% | 4 | 130% |

| Energy Management | Optimizing energy usage through real-time monitoring. | Cuts energy costs by 20% | 5 | 140% |

| Virtual Simulation | Simulating manufacturing processes before implementation. | Reduces design time by 30% | 8 | 115% |

| Augmented Reality (AR) | Using AR for training and maintenance tasks. | Increases operator efficiency by 35% | 7 | 160% |

| Blockchain for Transparency | Securely sharing data to improve trust among partners. | Improves data integrity and trust by 50% | 9 | 100% |

| Quality Control Automation | Automating inspection processes using AI. | Reduces detection errors by 40% | 3 | 125% |