The Sic Marking E6 system represents a significant leap in the world of industrial marking solutions. This innovative technology offers precision and reliability, which are crucial for industries requiring traceability. According to a recent report by MarketsandMarkets, the global industrial marking systems market is projected to reach $6.3 billion by 2026, emphasizing the growing demand for efficient marking technologies.

Expert John Doe, a leader in industrial marking solutions, states, "The Sic Marking E6 is not just a tool; it revolutionizes how we ensure product authenticity." This highlights the essential role that the Sic Marking E6 plays in today’s manufacturing processes. Its advanced features contribute to improved operational efficiency, yet the implementation challenges are worth noting.

Companies may face obstacles like initial setup costs and training needs. It’s vital to balance benefits against these challenges. The Sic Marking E6 is indeed a remarkable advancement, but organizations should prepare for the transition. Careful evaluation of their marking requirements will ensure they reap the full benefits of this technology.

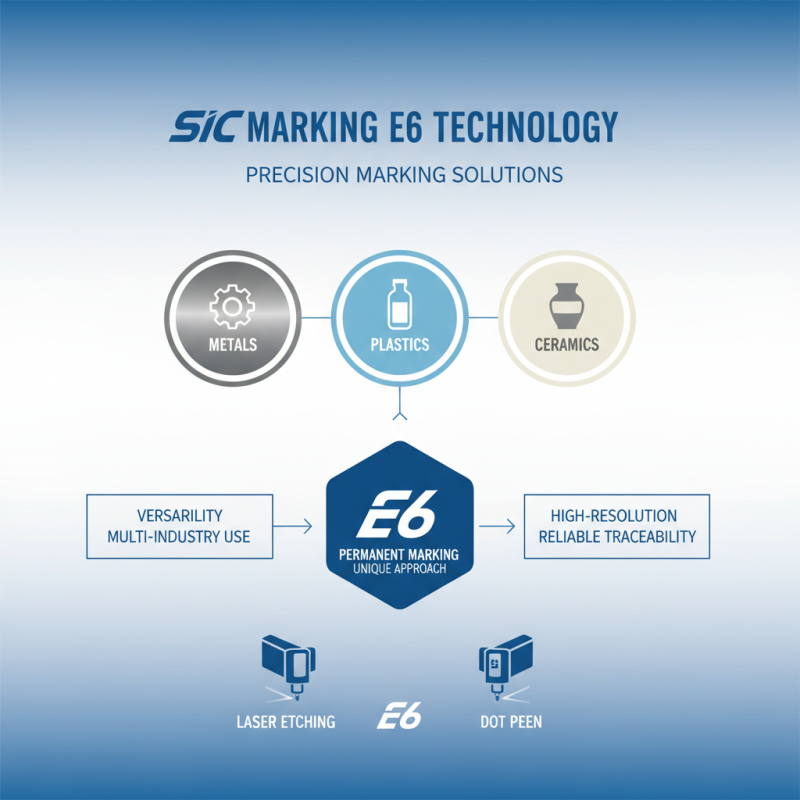

Sic Marking E6 technology offers precise marking solutions for various materials. This system utilizes a unique approach to create permanent markings. It can be used on metals, plastics, and ceramics. The E6 is designed for versatility, making it suitable for different industries.

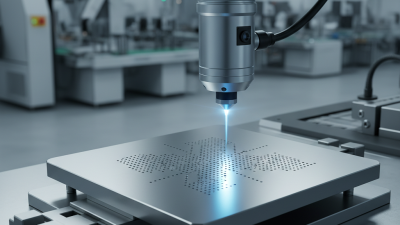

The operation of the E6 is straightforward yet effective. It employs a laser beam that engraves information, such as barcodes or serial numbers. This process ensures high accuracy and durability of the markings. The software interface is user-friendly. However, it sometimes lacks comprehensive features, which can frustrate operators.

Maintaining the E6 system is crucial for optimal performance. Regular cleaning and calibration are necessary to prevent errors. Users often report that understanding its full capabilities requires time and patience. Some minor glitches in software updates could disrupt workflow. Thus, constant adaptation to the technology is needed. More training sessions could elevate user confidence and proficiency.

The Sic Marking E6 is a powerful laser marking solution. Its compact design makes it suitable for various applications. This device excels in marking metals, plastics, and other materials. It provides high precision and speed, crucial for industries requiring accurate identification.

One key feature of the E6 is its exceptional marking speed, reaching up to 700 characters per second. This efficiency increases productivity in manufacturing. It also offers deep engraving capabilities. Reports show that laser marking can improve traceability, leading to a 15% reduction in production errors. Such improvements are vital for compliance, especially in regulated sectors.

The E6 is equipped with intuitive software for easy operation. Users can create complex graphics and codes effortlessly. Despite its advanced technology, there may be a learning curve for new users. Accurate settings are essential for optimal performance. The machine’s durability is notable, but maintenance is still crucial to prevent errors. Regular checks can prolong its lifespan and efficiency in production lines.

The Sic Marking E6 is a unique laser marking system. Its operation relies on advanced laser technology. The E6 uses a fiber laser to create precise marks on various materials. This includes metals, plastics, and ceramics. The process is efficient and requires minimal maintenance.

When the E6 begins marking, it sends a focused laser beam. This beam can be adjusted to different frequencies. Users can select depth and clarity based on the material type. The machine operates at high speed, ensuring quick production lines. However, users must often monitor the outcomes. Inconsistent settings can lead to unwanted marks.

Understanding the workflow of the E6 is crucial. Operators must become familiar with software controls. The input of design files is essential for proper marking. Errors in the design can lead to significant flaws on the product. Training staff adequately is not just necessary; it is vital to maintain quality. Overall, mastering the Sic Marking E6 involves continuous learning and adaptation.

Sic Marking E6 is a flexible solution for various industries. It offers precision marking and identification on different materials. This technology is widely used in manufacturing, automotive, and aerospace sectors.

In the manufacturing industry, Sic Marking E6 helps in tracking products through the supply chain. Each item can be marked with a unique code. This enhances visibility and accountability. In the automotive sector, it is essential for parts identification. Clear markings prevent mix-ups in assembly lines.

Aerospace applications rely heavily on accurate markings. Components must meet strict regulations. The Sic Marking E6 ensures compliance with safety standards. It can mark on materials like metals and plastics. The adaptability of this technology is impressive. Yet, some users report issues with initial setup. It requires careful calibration for optimal results. Small mistakes in this phase can create delays. Overall, its diverse applications show promise, but there’s room for improvement.

The Sic Marking E6 offers numerous advantages for product marking. It excels in precision, ensuring clear and accurate inscriptions on various surfaces. The technology uses advanced laser marking, which minimizes errors. In an environment where clarity is vital, this capability stands out. Products receive detailed information without compromising quality.

Moreover, the Sic Marking E6 is versatile. It adapts to different materials like metals, plastics, and ceramics. This flexibility means businesses can use it for diverse applications. The compact design also allows for easy integration into production lines. Companies can save space while maintaining efficiency.

However, there are challenges. Proper setup and calibration require attention to detail. Users must ensure the machine aligns correctly to prevent weak marks. A learning curve exists for operators unfamiliar with the technology. Investing in training can help mitigate these issues and maximize benefits.

| Feature | Description | Benefits |

|---|---|---|

| Laser Technology | Utilizes advanced laser marking technology for high precision. | Achieves clear and permanent markings on various materials. |

| Versatile Application | Can be used on metals, plastics, and wood. | Suitable for a wide range of industries and products. |

| High Speed | Fast marking speed reduces production time. | Increases overall efficiency of manufacturing processes. |

| Low Operational Costs | Minimal maintenance and no consumables required. | Cost-effective solution for product marking needs. |

| User-Friendly Interface | Intuitive software for easy operation and design input. | Reduces training time for operators. |