In today's fast-paced manufacturing environment, the need for precision and efficiency has never been more critical. One technique that stands out in the realm of product identification and traceability is sic marking e6. According to a market research report by Smithers Pira, the global market for product marking and coding is projected to reach $24 billion by 2025, with an increasing focus on technologies that enhance operational efficiency and compliance. Sic marking e6, known for its clarity and durability, plays a pivotal role in enabling manufacturers to meet stringent regulatory requirements and consumer demands for enhanced traceability.

Moreover, industries such as automotive, electronics, and food and beverage are increasingly adopting advanced marking technologies to streamline their processes and mitigate errors. A recent study from MarketsandMarkets indicates that the adoption of automated marking solutions, including sic marking e6 techniques, can reduce operational costs by up to 30%, significantly impacting the bottom line. This guide aims to provide comprehensive insights into sic marking e6 techniques and tips for success, empowering businesses to harness its full potential and gain a competitive edge in the market.

The Sic Marking E6 is a state-of-the-art marking system designed for high precision and efficiency in industrial environments. This innovative machine utilizes advanced laser technology to create permanent markings on various materials, including metals, plastics, and ceramics. Its adaptability makes it an ideal choice for a wide range of applications, such as product identification, traceability, and branding. Furthermore, the E6’s user-friendly interface allows operators to easily program complex marking patterns and adjust settings to suit specific tasks, minimizing downtime and maximizing productivity.

One of the standout features of the Sic Marking E6 is its high-speed operation. The system is capable of marking at impressive speeds without sacrificing quality, ensuring that production lines can maintain their pace while delivering accurate and clear markings. Additionally, the E6 is equipped with advanced cooling and dust protection systems, enhancing its durability and reliability in challenging manufacturing conditions. With its focus on precision, efficiency, and versatility, the Sic Marking E6 stands out as a leading solution for industries looking to implement effective marking strategies.

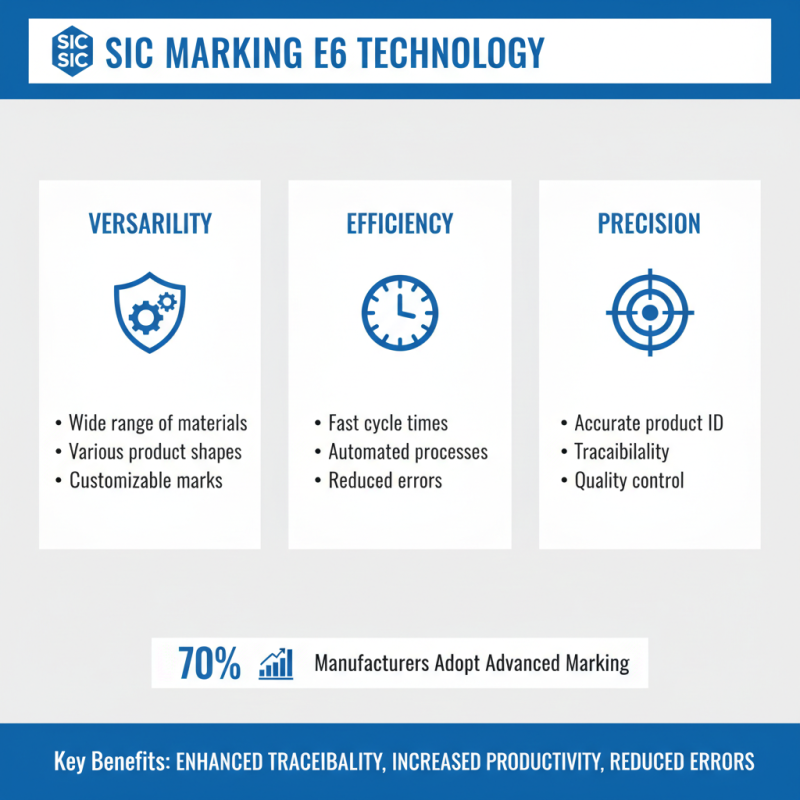

Sic marking E6 technology plays a vital role in modern manufacturing and product identification. This innovative marking solution offers versatility, efficiency, and precise results. According to recent industry reports, over 70% of manufacturers have adopted advanced marking technologies, highlighting the importance of effective implementation for operational success. With proper techniques, organizations can enhance traceability, reduce errors, and improve overall productivity.

To achieve effective Sic marking E6 operation, it is crucial to focus on the setup and calibration of the equipment. Ensure that the marking device is properly aligned and calibrated to prevent inconsistencies in output. Regular maintenance is also essential, as machines that are not adequately serviced can lead to increased downtime and operational disruptions. It was noted in a recent survey that businesses that conducted routine maintenance reported a 30% reduction in unplanned downtime.

Tips: When operating Sic marking E6 systems, always conduct comprehensive training sessions for your team. Ensuring that operators understand the capabilities and limitations of the technology maximizes efficiency and minimizes errors. Additionally, keep an eye on environmental factors such as temperature and humidity, as they can affect marking quality. Implementing these practices will not only improve marking precision but also contribute to enhanced quality control processes within the production line.

Sic marking with E6 technology offers numerous advantages, but it also presents specific challenges that practitioners may encounter. One common issue is achieving accurate depth and consistency in the marking process. Variations in material properties and surface conditions can lead to uneven markings. To overcome this, operators should regularly calibrate their equipment and conduct initial tests on sample materials to establish optimal settings before commencing full production runs. Consistent monitoring during the marking process can also help identify any deviations promptly, allowing for quick adjustments.

Another significant challenge is maintaining the integrity of the marked information, especially when dealing with items that undergo further processing or exposure to harsh environments. To address this, it is essential to select the right marking parameters and materials tailored to the application requirements. Utilizing protective coatings or selecting durable substrates can also extend the lifespan of the markings. Additionally, implementing stringent quality control practices can help ensure that all markings meet the necessary standards, reducing the likelihood of errors and enhancing overall efficiency in production.

Proper maintenance and care of Sic Marking E6 equipment is essential for ensuring optimal performance and longevity. Regular inspections should be conducted to check for any signs of wear or damage, particularly in critical components such as the laser lens and cooling system. Keeping the equipment clean is vital; accumulated dust and debris can hinder operation and affect marking quality. Utilize appropriate cleaning materials that won't damage the machinery, and ensure that any maintenance tasks are performed following the manufacturer's guidelines.

Additionally, it is crucial to maintain the software that operates the E6 equipment. Regular updates can enhance functionality and introduce new features that improve efficiency. Training staff on the proper handling and maintenance procedures not only reduces the risk of user error but also fosters a culture of care around the equipment. Finally, keeping a log of maintenance activities, including routine checks and repairs, can help in identifying trends or recurring issues that need to be addressed proactively. By implementing these best practices, businesses can ensure their Sic Marking E6 equipment remains reliable and efficient for years to come.

When utilizing the Sic Marking E6 system, there are several advanced strategies to enhance your efficiency and productivity. First, ensure that you have a clear understanding of the material you are working with. Different materials may require specific settings or adjustments to the marking parameters, including speed, power, and frequency. Taking the time to familiarize yourself with these settings can significantly improve the quality and speed of your work.

Another effective tip for maximizing efficiency is to maintain your equipment regularly. Regular maintenance not only helps in prolonging the life of the marking machine but also ensures that it operates at optimal performance. Clean lenses, check for any wear on components, and perform software updates when necessary. This proactive approach allows for smoother operations, reducing downtime and increasing overall productivity.

Lastly, consider implementing a systematic layout in your production area. Organizing the workflow can lead to quicker access to materials, tools, and the marking machine itself. Create a dedicated space where everything is readily available, allowing operators to work efficiently without unnecessary distractions. By focusing on a structured environment, you can streamline the marking process and enhance output significantly.