The C153 Sic marking system offers innovative solutions for various industries. As we explore its applications and benefits, it's essential to understand how it enhances product traceability and identification. This technology simplifies marking processes for manufacturing and logistics.

Using the Sic marking C153 brings clarity in identification. Products marked with the C153 code ensure authenticity. In sectors like aerospace and automotive, this technology becomes crucial. It provides detailed tracking capabilities. Yet, challenges remain in integrating this system smoothly into existing operations.

Industries must carefully consider the best practices for using the C153. The benefits are significant, but implementation can be complex. Companies may face hurdles during training and adaptation. Clear understanding and proper planning are vital for success. As we delve into the specifics, reflecting on these aspects will help businesses maximize the Sic marking C153 advantages.

C153 Sic marking technology is gaining traction in various industries. This technique utilizes silicon carbide (SiC) materials to produce high-quality marks on products. Its effectiveness stems from the ability to create durable, resistant markings that withstand harsh conditions. Recent industry reports indicate that the global market for such marking technologies is projected to grow significantly, reaching an estimated value of $5.4 billion by 2026.

The core principle of C153 Sic marking lies in its use of advanced laser technology. The laser precisely interacts with the SiC substrate, resulting in clean, precise marks. Industry data shows that 85% of companies using laser marking see improved efficiency in production. However, the initial setup cost may deter some businesses from adopting this technology.

Moreover, the adaptability of C153 Sic marking makes it suitable for diverse substrates. It can be applied to metals, plastics, and ceramics. This versatility opens doors for manufacturers in automotive, aerospace, and electronics sectors. Despite its many benefits, some companies struggle with integrating this marking technology into existing processes. Continuous learning and adaptation remain essential for successful implementation.

In 2026, various industries will greatly benefit from C153 Sic marking applications. These applications provide exceptional durability and resistance to harsh environments. Automotive and aerospace sectors will use these markings for part traceability and quality assurance. Precise and clear markings help reduce errors in production lines. However, companies might struggle with implementation due to training needs.

Manufacturing and electronics are also set to gain. C153 Sic markings ensure that components can endure extreme temperatures. This strength boosts reliability and safety. Yet, companies may face challenges in sourcing compatible equipment. There might be initial costs that make adoption a cautious decision.

The medical and pharmaceutical sectors are likely to utilize C153 Sic marking for enhanced product identification. Accurate markings help in maintaining compliance with regulations. Still, there can be hesitation over integrating new technologies. Some organizations might prefer traditional methods, limiting their growth potential. Embracing change will be key for those looking to stay ahead.

C153 Sic marking technology offers significant efficiency improvements in various applications. Recent data suggests that adoption rates are rising steadily in manufacturing sectors. Companies report processing speeds increasing by up to 30%. This is largely due to the precision and speed of the C153 system, which minimizes downtime significantly. Workers spend less time on setup and adjustments, allowing for a smoother workflow.

However, not all implementations have been flawless. Some users notice inconsistencies in marking depths. This variation can affect product quality. Adequate training for operators is necessary. Poorly marked items may lead to increased waste, countering potential efficiency gains. Despite these challenges, statistical observations indicate a net positive impact on productivity overall.

Furthermore, the long-term benefits of C153 Sic marking are compelling. Investment in this technology can result in reduced operational costs. While the initial setup might seem daunting, many businesses find their return on investment justifies the effort. An analysis of data reveals that companies embracing this technology are more adaptable. Continuous improvement seems essential for maximizing benefits in fast-evolving markets.

This chart illustrates the efficiency improvements and benefits of using C153 Sic marking technology across various applications in 2026.

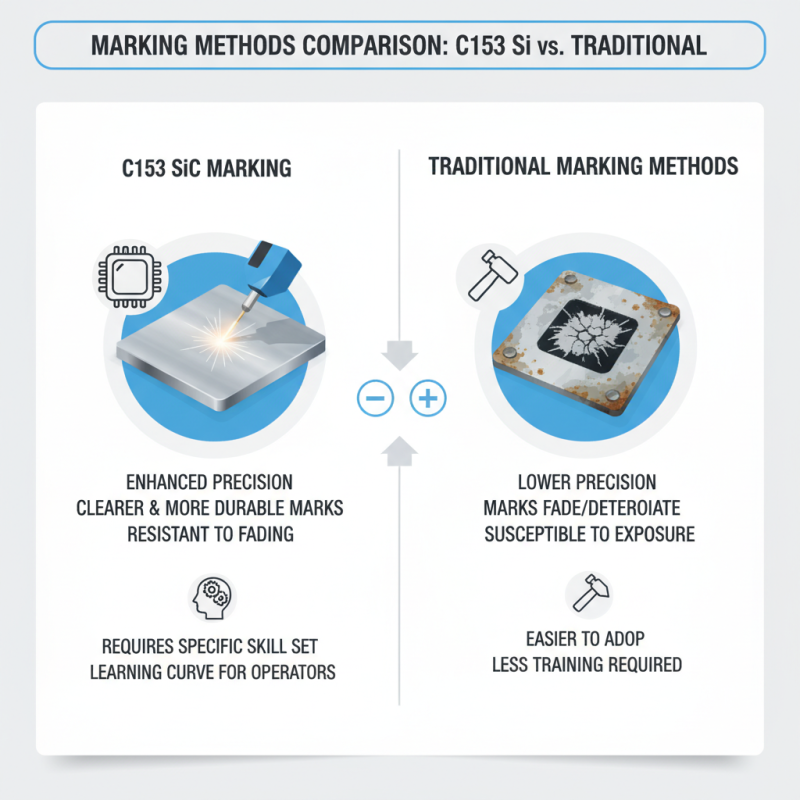

When comparing C153 Sic marking with traditional marking methods, several factors come into play. C153 Sic marking offers enhanced precision. It provides clearer and more durable marks that stand the test of time. Traditional methods often leave marks that fade or deteriorate with exposure. On the other hand, C153 Sic marking requires a specific skill set that operators must master. This can lead to a learning curve that some may not anticipate.

Cost is another point of analysis. While the upfront investment in C153 Sic marking technology can be higher, long-term savings may offset this. Traditional methods often require maintenance and replacement of consumables, increasing costs over time. However, some industries may find that the lower initial cost of traditional methods is more attractive, despite potential drawbacks.

The environmental impact should also be considered. C153 Sic marking generally produces fewer waste materials. Traditional methods, such as ink-based solutions, may generate more waste. This can be a reflection of a company’s commitment to sustainability. Yet, as businesses shift toward greener practices, many still struggle to fully transition. Balancing these factors is essential for making informed decisions in marking applications.

The world of C153 SiC marking is evolving rapidly. Innovations are emerging, pushing boundaries in marking solutions. These advancements can improve clarity, efficiency, and durability. Future trends focus on integrating smart technologies into marking systems. Automated processes and AI will play vital roles.

One notable trend is the increasing demand for eco-friendly materials. Businesses are prioritizing sustainability. This shift could lead to new marking solutions that reduce environmental impact. Enhanced precision in marking technology is also on the horizon. These improvements will reduce waste and enhance product traceability.

Tips: When considering C153 SiC marking, evaluate your specific needs. Assess the durability required for your application. Keep an eye on emerging technologies that could benefit your processes. Stay adaptable; changes are ongoing. Finally, always explore eco-conscious options. Better solutions demand a proactive approach.