In today's fast-paced industrial landscape, the DMC data matrix plays a critical role. This technology offers innovative solutions across various sectors. Its unique ability to encode large volumes of data into a small space makes it indispensable.

Manufacturers, retailers, and logistics companies leverage the DMC data matrix for better tracking and inventory management. For instance, it allows real-time updates on stock levels. This can enhance efficiency but may also lead to over-reliance on technology. Businesses often need to evaluate their systems continuously.

Moreover, the DMC data matrix supports customer engagement. By scanning codes, consumers access product information quickly. However, some may find this overwhelming or confusing. Balancing technology with user experience remains essential for successful implementation. The use of DMC data matrix continues to evolve, opening doors to new applications and insights.

DMC Data Matrix technology has transformed various industries, offering unique solutions for identifying and tracking products. This two-dimensional barcode can store large data volumes. Unlike traditional barcodes, the DMC Data Matrix is compact and can be printed at a smaller size while maintaining readability. A report from the International Data Corporation indicates that industries using DMC data saw a 20% reduction in scanning errors. This improvement is crucial for inventory management and product traceability.

Additionally, the healthcare sector has embraced DMC technology. Hospitals use Data Matrix codes for medication tracking. A study published in the Journal of Pharmaceutical Sciences reveals that implementing DMC led to a 30% decrease in medication errors. This not only enhances patient safety but also streamlines operational efficiency. However, challenges remain. Some staff may struggle with training or system integration. Reports suggest a need for better education on DMC technology's benefits and usage.

In the manufacturing industry, DMC Data Matrix codes improve production monitoring. They allow real-time tracking of components. According to a recent Manufacturing Tech Insights survey, companies that utilized DMC increased their productivity by 15%. However, the transition requires adaptation. Some employees face difficulties in changing from traditional practices to advanced systems. Balancing innovation with workforce readiness is a critical issue stakeholders must address.

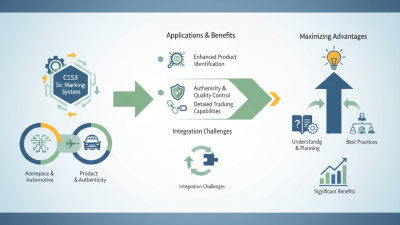

The DMC Data Matrix plays a crucial role in modern manufacturing and supply chain management. This technology enables manufacturers to encode product information in a compact format. Scanning a Data Matrix allows for quick access to details such as production dates and batch numbers. With the rise of automation, these codes enhance operational efficiency. However, implementing this technology requires careful integration across systems.

In supply chains, DMC Data Matrices improve traceability. They allow tracking of products from origin to the final consumer. Each step can be logged and monitored. This visibility reduces errors and enhances accountability. Despite these benefits, some companies struggle with staff training and system updates. These challenges can slow down progress. Regular assessments of staff readiness and system compatibility are essential. Overlooking these aspects could lead to inefficiencies and lost opportunities in a competitive market.

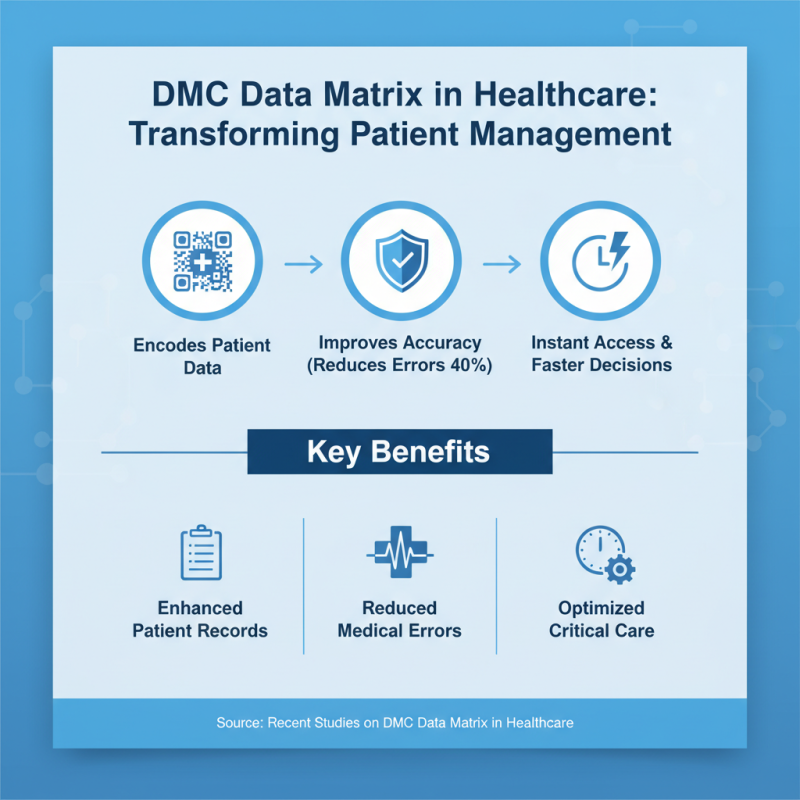

The use of DMC Data Matrix in healthcare has transformed patient management significantly. It offers a way to encode patient data in a compact format. This technology improves the accuracy of patient records, reducing errors by up to 40% according to recent studies. By scanning these codes, healthcare providers gain instant access to vital information. This leads to faster decision-making during critical situations.

Moreover, the DMC Data Matrix enhances medication tracking. It helps prevent mistakes with prescriptions and dosage. A report from the Global Health Data Initiative shows that nearly 7,000 deaths annually occur due to medication errors. Implementing Data Matrix codes can alleviate this issue. Patients benefit from safer treatments and tailored care plans based on their history encoded in the matrix.

Despite these advances, challenges remain. Not all healthcare facilities have adopted this technology. Some struggle with integration into existing systems. Training staff on new processes also poses a hurdle. As the industry pushes for digital transformation, reflection on these barriers is essential. Effective implementation requires overcoming these obstacles to ensure every patient reaps the benefits of enhanced management through DMC Data Matrix.

DMC Data Matrix codes are revolutionizing retail and consumer engagement. These two-dimensional codes provide essential information at a glance. They can store a wealth of data, like product details and inventory levels. When scanned, users can access promotions, reviews, and demos right away. This immediate access drives customer interest and enhances user experience.

Yet, the implementation is not without challenges. Some consumers may struggle with scanning these codes. Depending on a smartphone camera can be problematic. Not every retail environment supports this technology equally. Additionally, if not updated regularly, the information can become outdated. This misalignment can lead to frustration and mistrust among users.

Despite these issues, the impact of DMC Data Matrix codes is significant. They allow for personalized shopping experiences and streamlined operations. Customers enjoy discovering new products through QR code-linked content. For businesses, understanding consumer behavior becomes easier. Enhanced data collection leads to informed business decisions. By addressing potential shortcomings, industries can better leverage this technology.

| Use Case | Industry | Description | Impact on Engagement |

|---|---|---|---|

| Inventory Management | Retail | Streamlines tracking of products, reducing stock discrepancies. | Enhances operational efficiency and improves customer satisfaction. |

| Product Authentication | Pharmaceuticals | Ensures that products are genuine, protecting consumers from counterfeit. | Builds trust and loyalty among consumers. |

| Traceability | Food & Beverage | Tracks the journey of food products from farm to table. | Increases transparency, boosting consumer confidence. |

| Customer Engagement | E-commerce | Facilitates personalized marketing through data capture. | Enhances personalized shopping experiences. |

| Streamlined Checkout | Retail | Enables quick scanning at point of sale for faster transactions. | Improves overall customer satisfaction with reduced wait times. |

| Supply Chain Efficiency | Logistics | Optimizes shipping and handling processes. | Minimizes delays and enhances delivery accuracy. |

| User Feedback Collection | Consumer Goods | Gathers customer insights through scanable codes. | Fosters product improvements and customer engagement. |

| Dynamic Pricing | Retail | Enables real-time pricing updates based on inventory. | Increases sales by optimizing value for consumers. |

| Loyalty Programs | Retail | Tracks customer purchases to reward loyalty. | Strengthens customer retention through rewards. |

| Event Ticketing | Entertainment | Facilitates easy access and verification at venues. | Enhances attendee experience with quick entry. |

DMC Data Matrix is gaining traction across various sectors. Recent reports indicate that its adoption has surged by over 40% in logistics and supply chain management. Companies utilize this technology for precise tracking and inventory management. It streamlines processes, but challenges persist in integration with existing systems.

The food and pharmaceutical industries also show promising trends. According to a study, 30% of companies report enhanced traceability with DMC Data Matrices. This innovation helps ensure product safety, yet the need for standardization remains a hurdle. The future may see collaborations for unified protocols, but the varied implementation strategies could delay progress.

Moreover, industries are exploring AI integration with DMC Data. This advancement could revolutionize data analysis and decision-making. Even so, some organizations report difficulties in aligning data processing capabilities. Future trends hint at potential solutions, but adapting to these changes may require significant adjustments. As industries advance, the balance between innovation and practicality continues to challenge stakeholders.

This chart illustrates the top 10 applications of DMC Data Matrix technology across various industries, showcasing the versatility and innovation in its utilization.