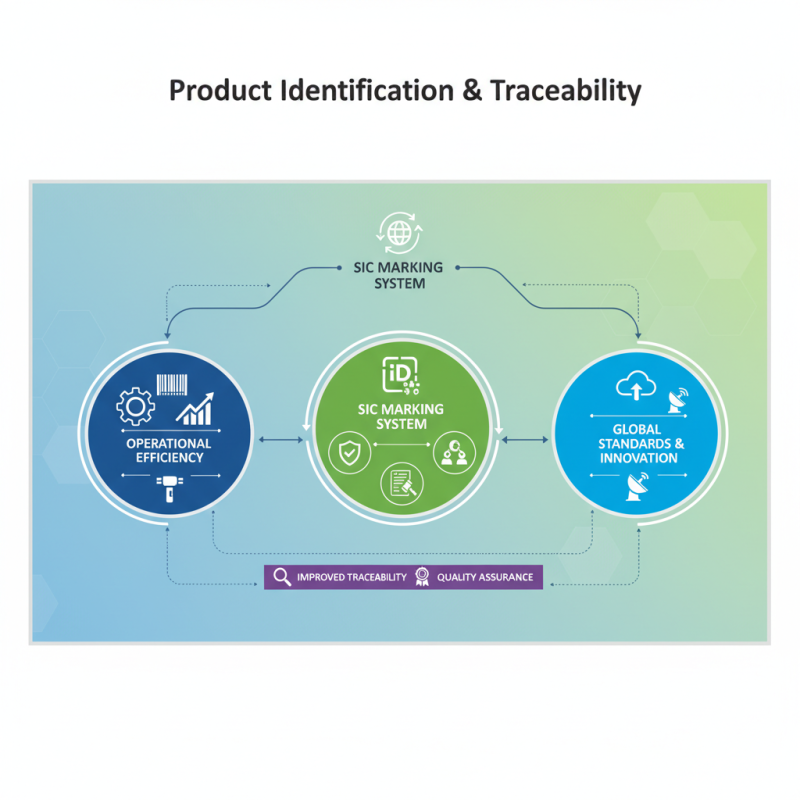

In today’s rapidly evolving manufacturing landscape, effective product identification has become a cornerstone for operational efficiency and compliance. The SIC Marking Manual serves as a crucial resource for organizations seeking to implement robust identification systems, as it aligns with industry standards and regulatory demands. According to the latest report by the International Organization for Standardization (ISO), nearly 85% of manufacturing companies recognize the importance of traceability in enhancing product quality and safety, which significantly emphasizes the relevance of the SIC marking system.

David Thompson, a leading expert in product identification strategies, once remarked, “Understanding the SIC Marking Manual is not just about compliance; it’s about creating a culture of accountability through precise and persistent product tracking.” This perspective highlights the manual's integral role in facilitating a transparent identification process that caters to both internal operational needs and external regulatory requirements. As industries increasingly adopt advanced technologies such as blockchain and IoT for tracking purposes, the principles outlined in the SIC marking manual become even more pertinent, ensuring that companies remain competitive and responsive to market demands.

In conclusion, as the landscape of product identification continues to shift, leveraging the SIC marking manual becomes essential for organizations aiming to improve traceability, accountability, and compliance. By adopting its guidelines, businesses can not only enhance their operational frameworks but also solidify their commitment to quality assurance in an interconnected world.

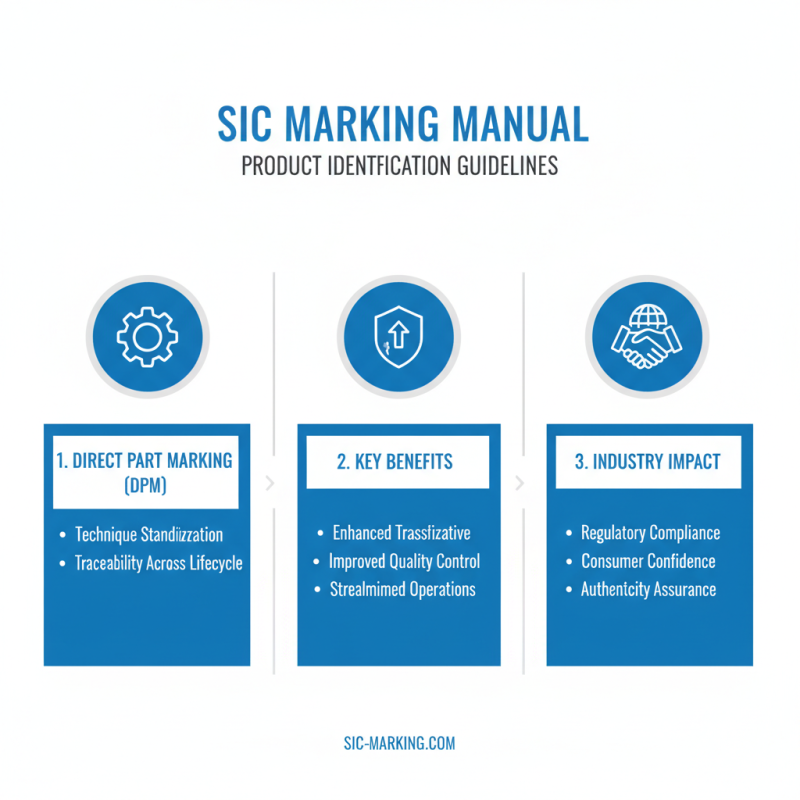

The SIC Marking Manual serves a crucial role in standardizing product identification across various industries. Its primary purpose is to provide guidelines for implementing Direct Part Marking (DPM) techniques, ensuring that products can be easily traced and identified throughout their lifecycle. By adhering to these guidelines, manufacturers can enhance traceability, improve quality control, and streamline operations. This effectiveness in identification not only aids compliance with industry regulations but also fosters consumer confidence in product authenticity.

Tips for utilizing the SIC Marking Manual include familiarizing yourself with the sections that outline different marking techniques and materials. Understanding the specific methods suited for your products will help you select the best approaches based on durability and visibility. Additionally, consider conducting training sessions for your team to ensure everyone understands the importance of compliance with the marking standards. Regular audits of your marking processes can also help in identifying gaps and areas for improvement, ensuring a seamless product identification strategy.

When implementing the guidelines, remember that consistency is key. Use standardized markings across similar product categories to avoid confusion. Moreover, maintain clear documentation of your marking practices which not only assists in compliance but also serves as a valuable resource for future reference. This comprehensive understanding of the SIC Marking Manual paves the way for effective product identification, enhancing overall operational efficiency.

The SIC marking system is a comprehensive approach designed to enhance product identification across various industries. At the core of this system lies a structured framework that includes unique identification codes, symbols, and additional relevant information that create a standardized method for marking products. These components ensure that products can be tracked throughout their lifecycle, facilitating quality control, compliance, and traceability.

One of the key components of the SIC marking system is the use of standardized codes that provide essential information about the product, including its origin, specific characteristics, and compliance with industry standards. Additionally, the incorporation of recognizable symbols allows for quick visual identification, reducing the potential for errors during handling, inventory management, and distribution. Furthermore, these markings can be complemented by digital elements, such as QR codes or NFC tags, enabling access to comprehensive product data through mobile devices, thereby enhancing transparency and informed decision-making in supply chains.

| Component | Description | Application | Benefits |

|---|---|---|---|

| SIC Code | Unique identifier for products, indicating the product class. | Used in product registration and compliance checks. | Enhances traceability and legal compliance. |

| Marking Label | Physical label that contains the SIC code and related information. | Affixed to products for easy identification. | Ensures accessibility of product information to users. |

| Documentation | Guidelines for proper usage and compliance with the SIC marking system. | Essential for manufacturers to follow legal requirements. | Reduces risk of non-compliance and associated penalties. |

| SIC Database | A repository containing all SIC codes and related information. | Accessed by manufacturers and authorities for reference. | Facilitates global standardization and consistency. |

Understanding the SIC marking manual is crucial for effective product identification, especially for manufacturers and distributors. The SIC (Standard Industrial Classification) marking system simplifies the categorization of products, enabling businesses to comply with industry regulations and streamline their supply chain processes. By following a step-by-step guide, users can navigate the complexities of the SIC system, ensuring that their products are properly classified and identified.

To start, familiarize yourself with the various SIC codes relevant to your product category. This requires a careful study of the SIC marking manual, which outlines the structure and purpose of each code. Once you identify the appropriate codes for your products, you can begin the marking process. This involves applying the correct SIC code to your labels, packaging, and any accompanying documentation. It's essential to ensure accuracy in this step, as incorrect codes can lead to confusion, compliance issues, or even shipping delays.

Finally, regularly review and update your SIC codes as needed. Industry standards and classification systems evolve, and staying informed about these changes is vital for effective product identification. By efficiently managing your SIC marking process, you not only enhance product traceability but also foster better communication with distributors and customers, thereby improving overall product lifecycle management.

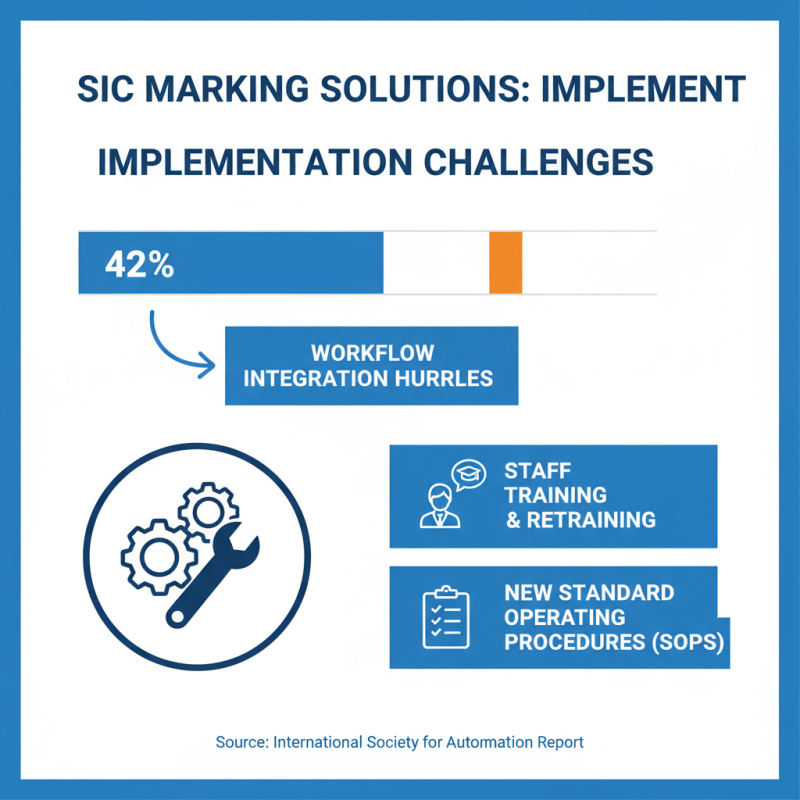

Implementing SIC marking solutions can present several challenges that businesses must navigate to achieve effective product identification. One of the primary hurdles is the integration of SIC marking systems with existing production processes. According to a report by the International Society for Automation, nearly 42% of organizations reported difficulties in modifying their current workflows to accommodate new marking technologies. This adaptation often requires significant investments in training and retraining staff, as well as the development of new standard operating procedures to ensure compliance and effectiveness.

Another challenge lies in the selection of suitable printing techniques that align with the product materials and environments. A study published by the Packaging Machinery Manufacturers Institute indicates that improper marking methods can lead to scannability issues, with nearly 30% of products failing to meet industry identification standards due to inadequate marking. Furthermore, consistency in the marking process is crucial; variations in ink viscosity or print speed can result in unreadable codes, ultimately leading to costly delays in the supply chain. As industries continue to adopt SIC marking solutions, addressing these challenges will be vital for enhancing product traceability and ensuring compliance with regulatory requirements.

Understanding the SIC marking manual is crucial for businesses that aim to comply with product identification standards. To effectively utilize this manual, companies should first familiarize themselves with the established guidelines. This includes recognizing the importance of accurate and consistent marking throughout the production and distribution processes. Maintaining a clear and standardized marking system not only facilitates traceability but also enhances consumer trust in the products.

Best practices emphasize the integration of SIC marking into the company's quality control and compliance procedures. Regular training sessions for staff can ensure that everyone understands the documentation and marking processes. Additionally, investing in quality marking tools and technologies can streamline the identification methods used. Companies should also conduct periodic audits to assess compliance with the SIC manual. This proactive approach helps identify areas for improvement and ensures adherence to the marking standards, ultimately leading to increased operational efficiency.

This chart illustrates the levels of product identification compliance with the SIC Marking Manual, categorizing the number of products into three compliance levels: Full Compliance, Partial Compliance, and Non-Compliance.