In the fast-evolving landscape of product identification, the SIC Marking E6 stands out. Experts like John Smith, a leading authority in marking technology, emphasize its importance: "Effective identification drives brand integrity and consumer trust." This sentiment resonates strongly as businesses seek robust solutions in 2026.

SIC Marking E6 offers cutting-edge technology for durable and precise product marking. Its versatility caters to various industries, enhancing traceability and compliance. However, some companies still struggle. They overlook the need for ongoing training and adaptation. This can lead to misuse of the system, diminishing its potential benefits.

As we progress into a new era, embracing innovations like the SIC Marking E6 is crucial. Industries must reflect on their current practices and identify areas for improvement. Only then can they unlock the full capabilities of this powerful tool for effective product identification.

SIC Marking E6 technology is designed for effective product identification. It offers a versatile solution for marking various materials, including metals and plastics. The E6 model utilizes laser marking, providing precision and clarity in every mark. This ensures that products remain identifiable over time, even in harsh environments.

Understanding how this technology works is essential. The E6 can adapt to different shapes and sizes, making it suitable for numerous applications. The user interface is intuitive, but new users may feel overwhelmed. Learning to navigate the settings can take time. The machine can mark quickly, yet improper settings might lead to unclear markings, necessitating experimentation.

It’s important to consider the quality of your markings. The E6 can deliver high-resolution results, yet consistent maintenance is crucial. Improper upkeep can result in equipment failure or inaccuracies. Regular checks on the laser and software updates can avoid many pitfalls. Users should be vigilant about wear and tear, observing how marks vary over time.

The SIC Marking E6 system offers several key features for efficient product identification. Its user-friendly interface makes it accessible for operators. The touchscreen display simplifies navigation, allowing quick adjustments. Compact design ensures it fits various production lines. Users can select from multiple marking options. This versatility supports diverse materials and surfaces.

Another significant aspect is the system's speed. It can mark items rapidly, which enhances production efficiency. The ability to integrate with existing workflows is advantageous. However, some users report occasional calibration issues. Regular checks can help maintain accuracy. The durability of the equipment is another point of reflection. While generally robust, some components may wear over time.

In 2026, the SIC Marking E6 will need to adapt. The evolving demands of industry require constant innovation. While its current features are functional, exploring additional capabilities is vital for future success. Emphasizing user feedback can lead to improvements. Balancing speed and precision remains a challenge, but worthwhile to pursue.

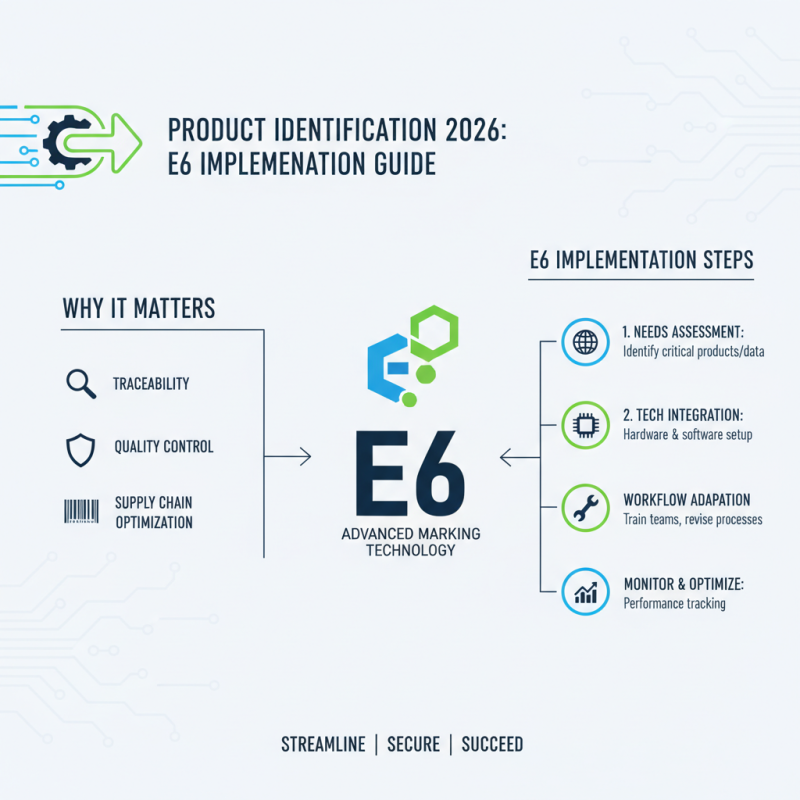

Product identification is critical in various industries. In 2026, using advanced marking technology like E6 can streamline this process. This guide will outline the steps to implement E6 effectively.

Begin by assessing your product types and their specific identification needs. Research from the International Organization for Standardization (ISO) suggests that 75% of companies experience labeling errors. Such mistakes can lead to lost time and revenue. Choosing the right materials for your E6 system is essential. Consider durability and readability. These factors play a significant role in long-term success.

Next, integrate E6 marking into your production line. Training staff is crucial. Only 60% of employees feel confident using new technologies, as per a recent industry report. Regular workshops and hands-on training can boost this confidence. Remember, smooth operation is vital, but there may be teething issues that require patience and fine-tuning. Monitor the marking process closely to ensure quality control is maintained. Adjustments might be necessary based on early feedback. This iterative approach helps in refining the system for better results in product identification.

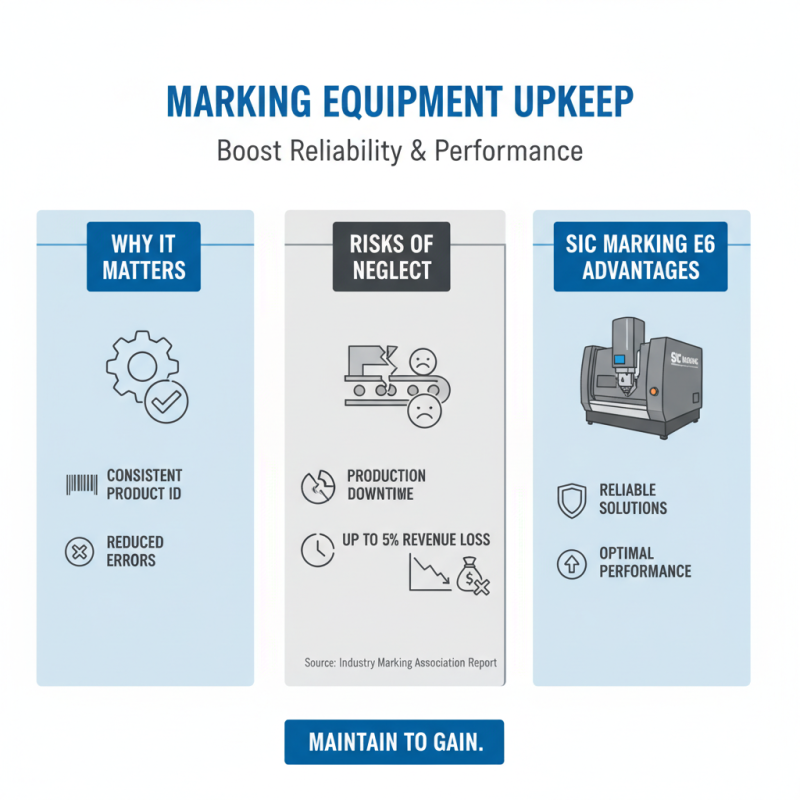

Maintaining your marking equipment is crucial for consistent product identification. The SIC Marking E6 offers reliable solutions for various industries. However, proper upkeep is essential for optimal performance. According to a report by the Industry Marking Association, equipment failure can significantly impact production, costing companies up to 5% of their annual revenue.

Regularly inspect the marking head for wear. This small step can prevent major errors. Ensure that the ink or laser cartridge is functioning properly. A malfunctioning cartridge can lead to inconsistent markings. Document everything; track maintenance logs to identify patterns in failures.

Here are some tips:

- Replace worn components without delay.

- Clean the marking area to avoid contamination.

- Train staff on the equipment’s best practices.

Neglecting these could lead to increased errors. Inconsistent product identification can hurt brand reputation. Reflect on how often you perform maintenance. Is it enough? Adjust your schedule if needed. Regular attention can save time and resources.

In 2026, product identification technologies are evolving rapidly. The use of advanced marking systems, such as SIC Marking E6, allows for greater precision and efficiency. Businesses must adapt to enhance traceability and compliance. As industries grow, so does the need for robust identification methods.

One trend to watch is the integration of automation. Automated marking can streamline processes. This reduces human error and increases productivity. However, it requires careful planning and training. Flaws in system integration can lead to costly mistakes.

Tips for success include investing in training. Employees should understand how to use the SIC Marking E6 effectively. Regular maintenance of marking equipment is essential. It ensures optimal performance over time. Additionally, staying updated on technology trends is crucial. Adapting to changes can help meet future challenges and market needs.

| Technology | Description | Benefits | Applications |

|---|---|---|---|

| Laser Marking | Utilizes a laser to engrave information onto products. | Permanent marking, high precision, suitable for various materials. | Electronics, automotive, aerospace. |

| Inkjet Printing | Sprays ink onto products to create codes and labels. | Cost-effective, versatile for different surfaces. | Food packaging, pharmaceuticals, logistics. |

| RFID Technology | Uses radio waves to automatically identify items. | No line of sight needed, can read multiple tags at once. | Inventory management, supply chain, retail. |

| QR Codes | 2D barcode that can be scanned by smartphones for information. | Easy access to digital information, engaging marketing tool. | Retail, advertising, event ticketing. |

| Data Matrix | Compact 2D code for encoding large amounts of data. | High data capacity, small footprint for tight spaces. | Healthcare, automotive parts, consumer goods. |