The challenge

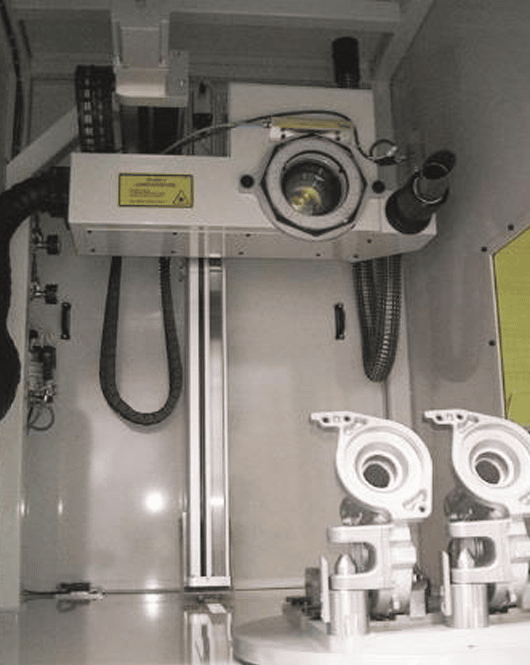

On the one hand, the marking station must take account of constraints relating to production and the environment:

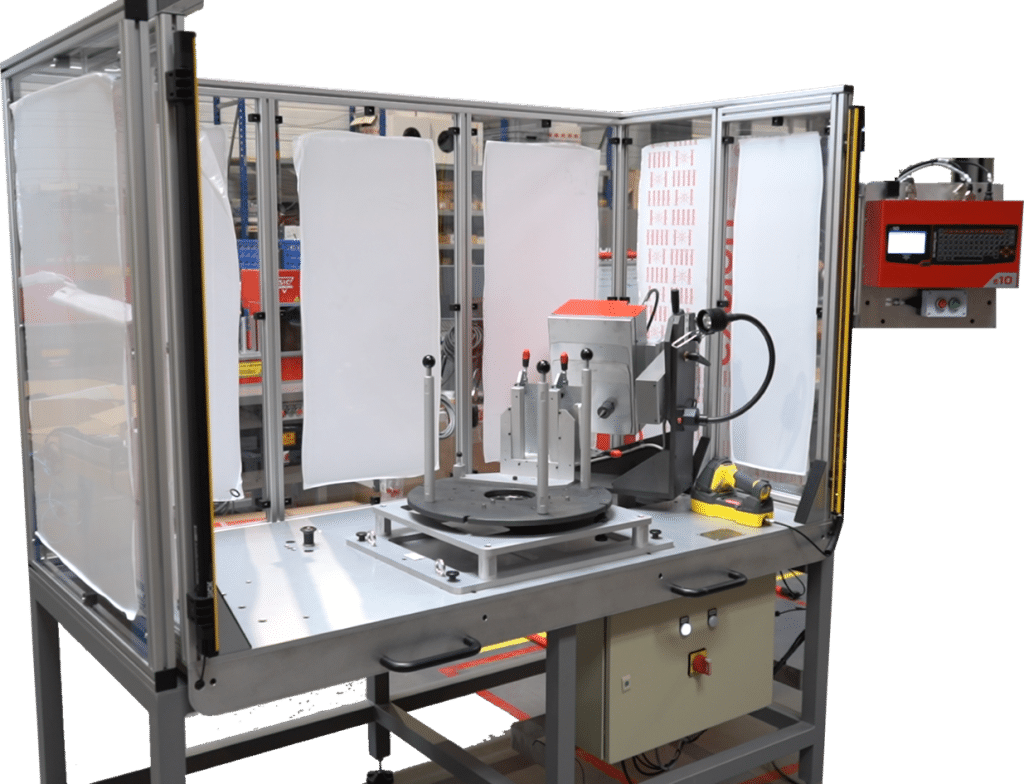

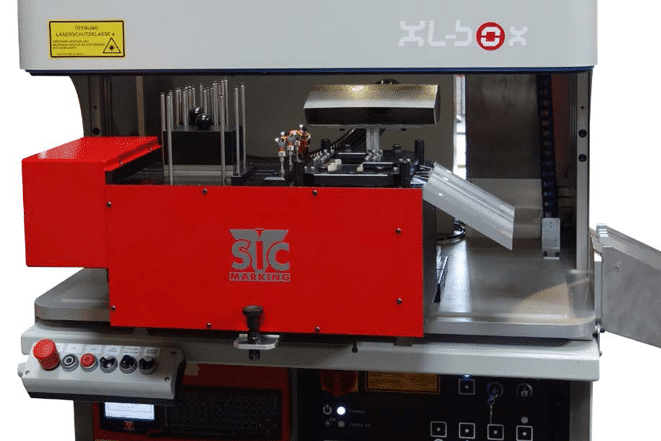

- A small footprint despite the variable size of parts (long parts with a height of 600 mm, mounted on a vertical D-axis, for example).

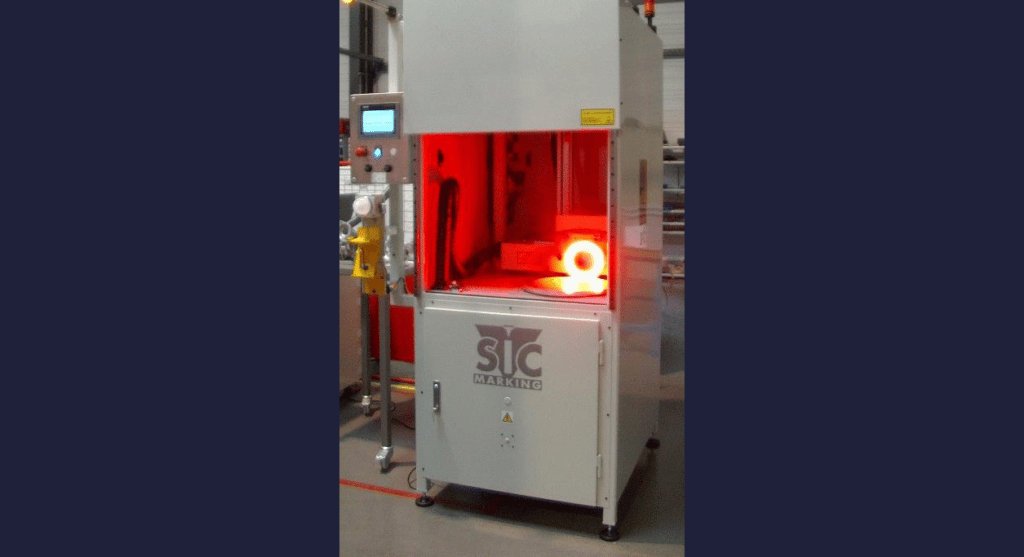

- Effective guards and easy access for maintenance for optimum protection of the machine because of dust and humidity.

On the other hand, the machine must be designed to satisfy productivity requirements.

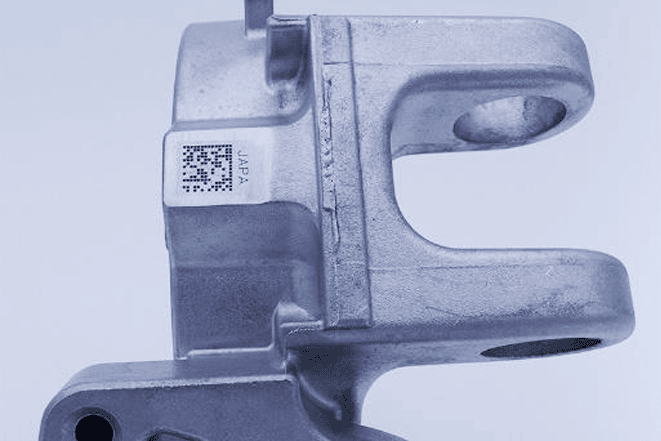

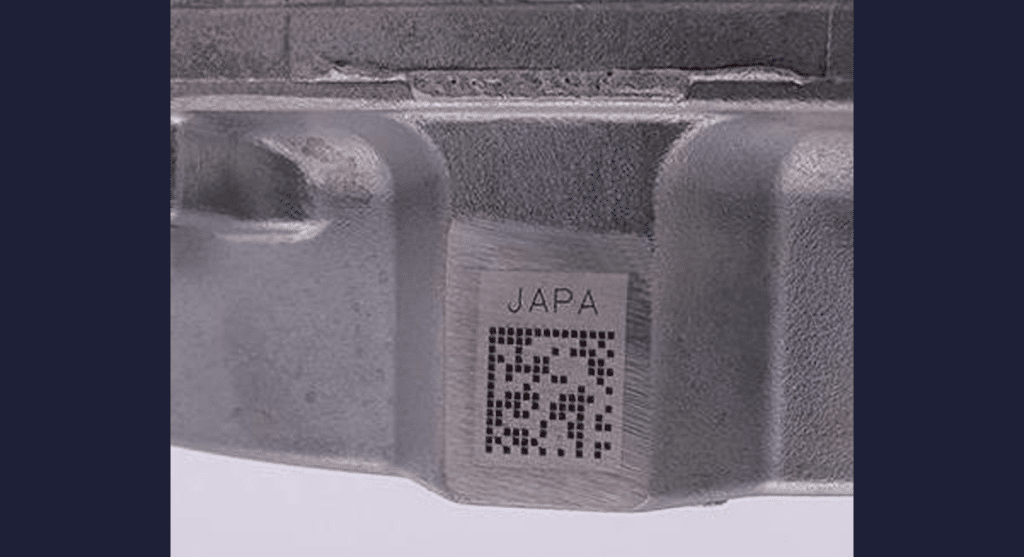

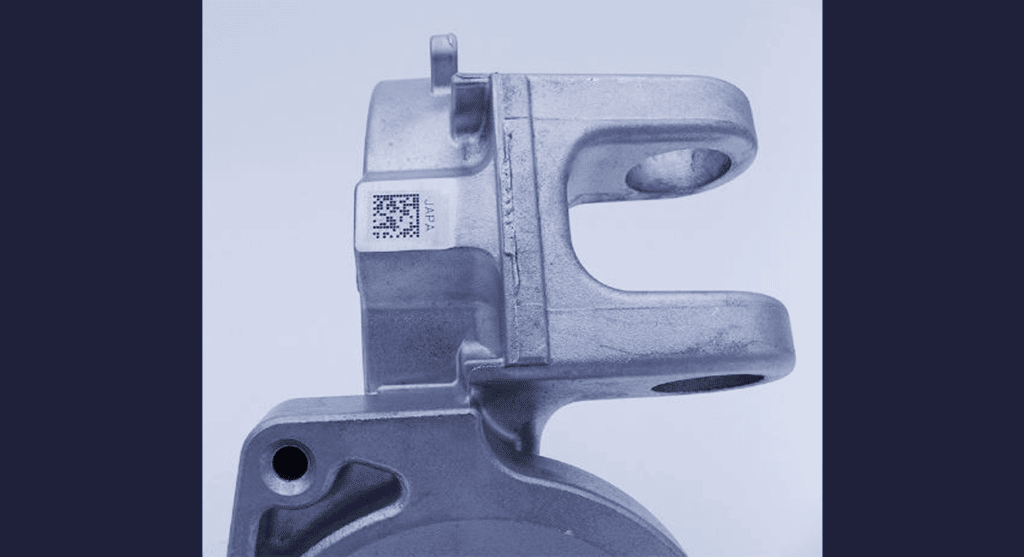

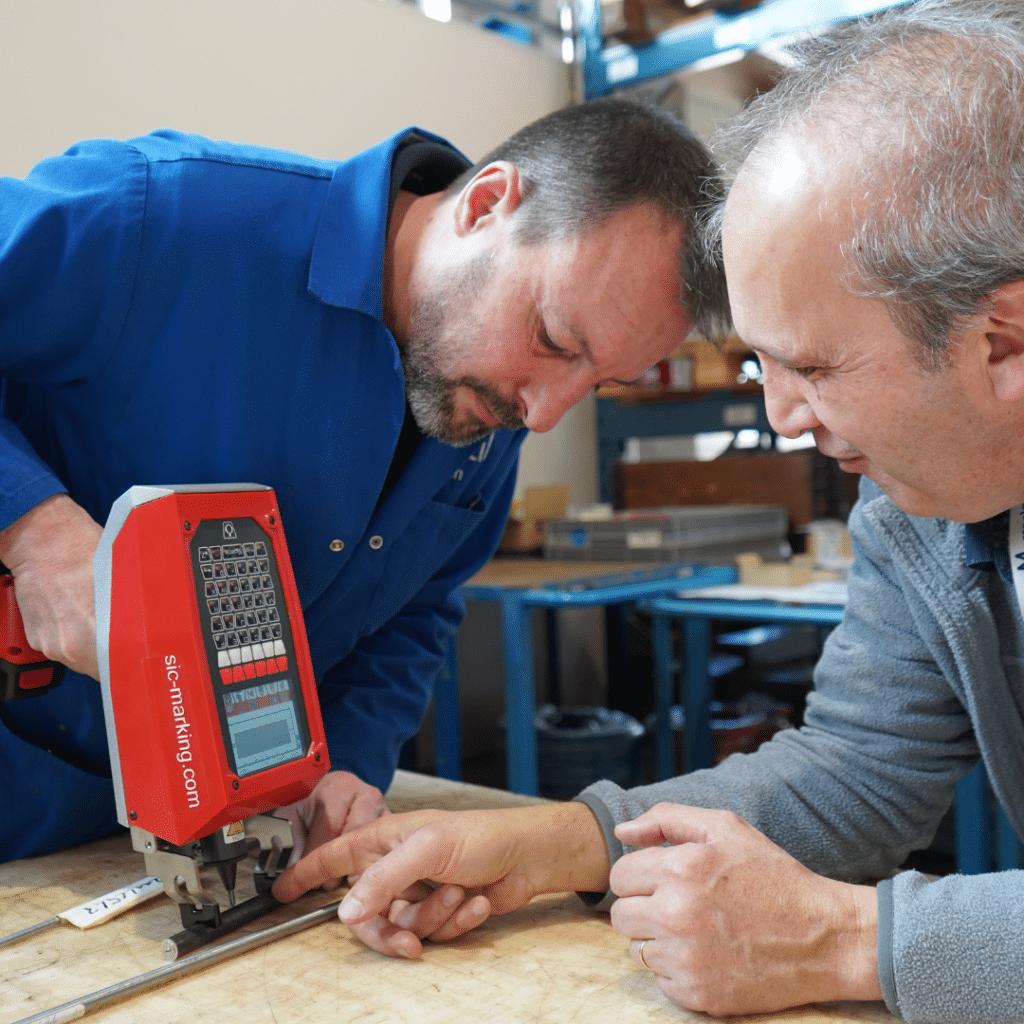

The manufacturer of cast aluminium parts wants an efficient station offering:

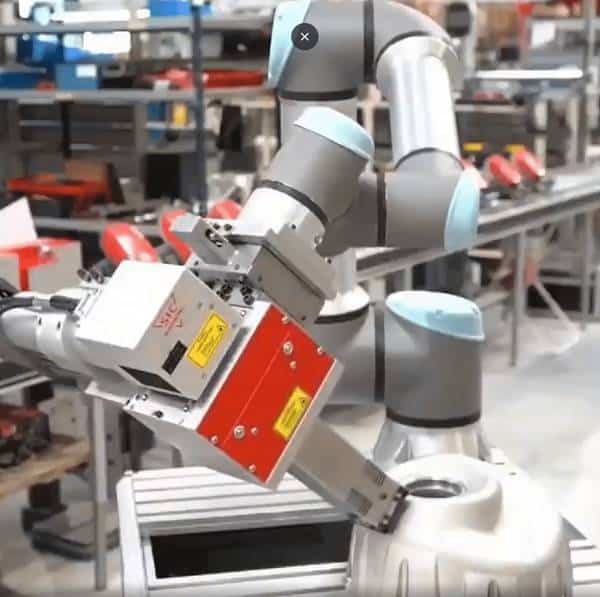

- An outstanding marking and parts handling speed,

- Very high quality marking, facilitating Data Matrix reading.