The challenge

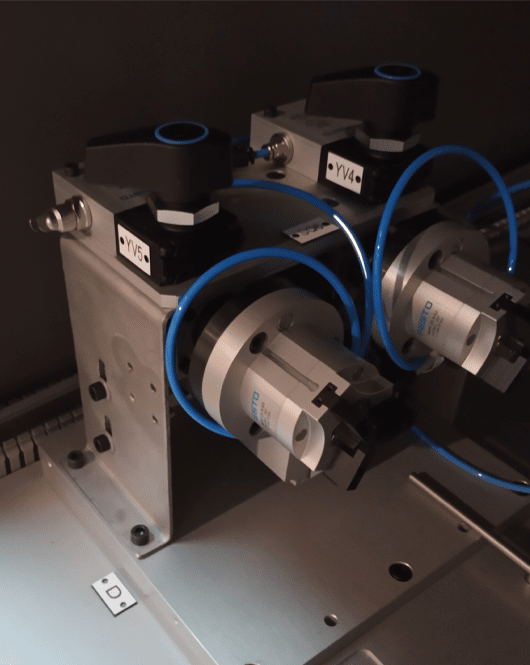

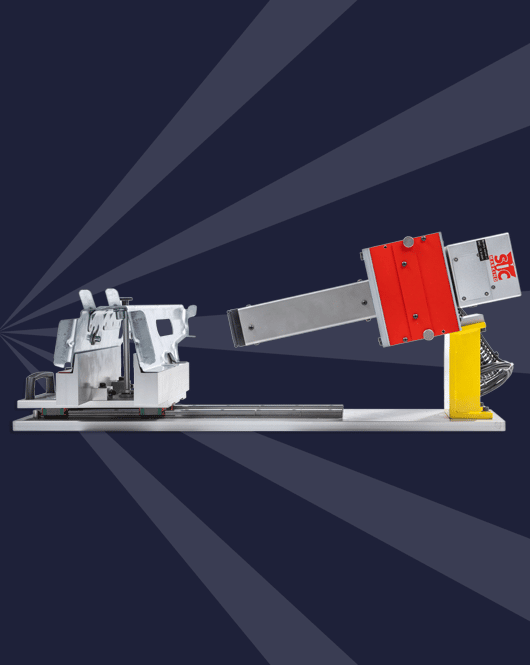

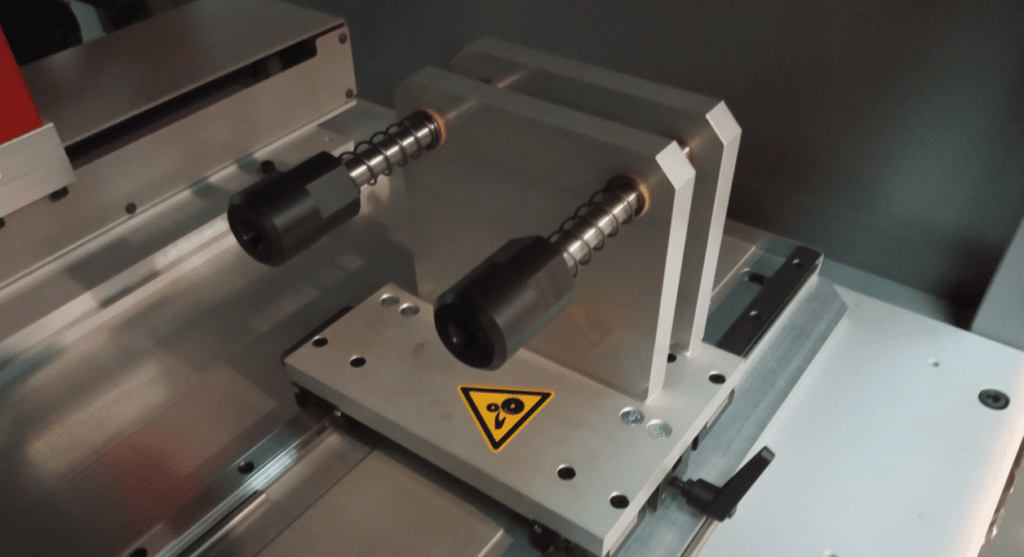

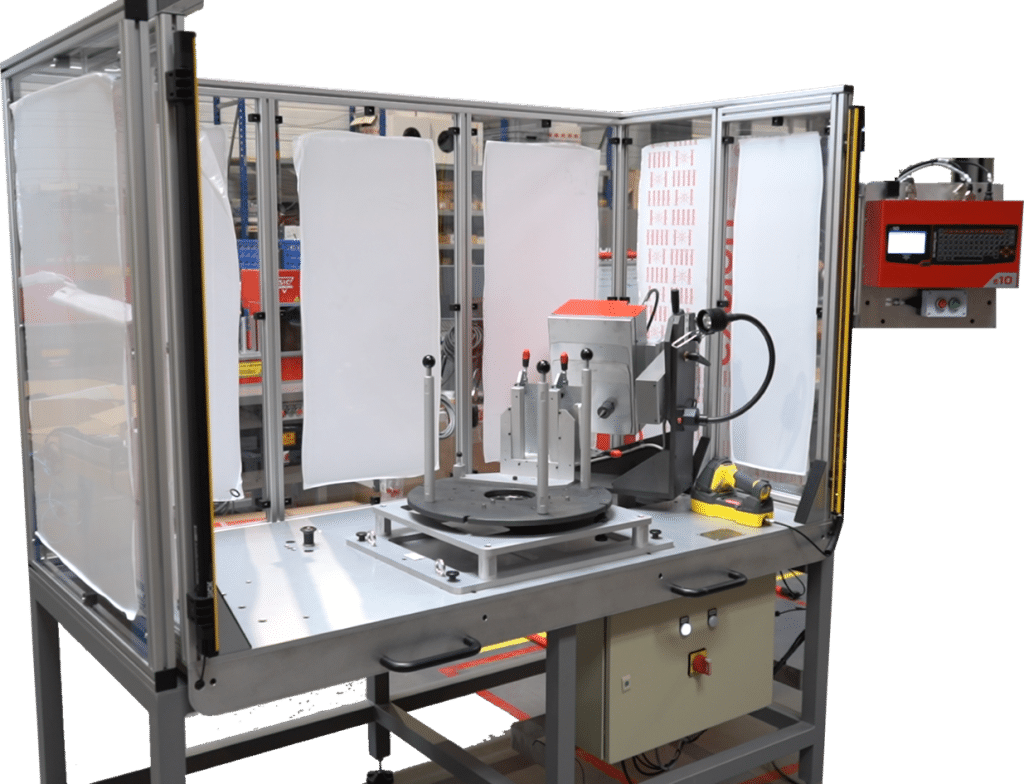

The solution needs to mark very long rods over 360 degrees, two at a time.

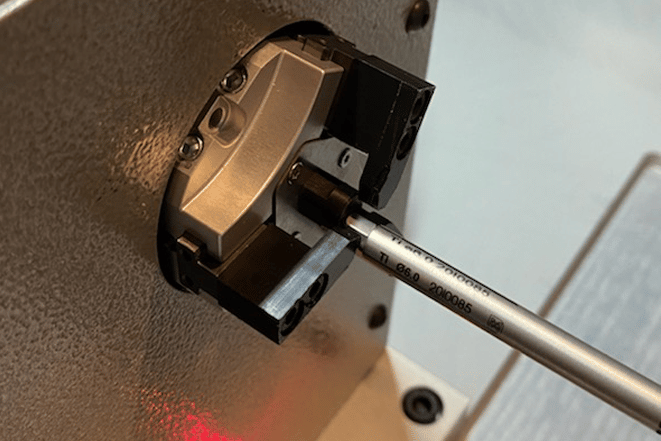

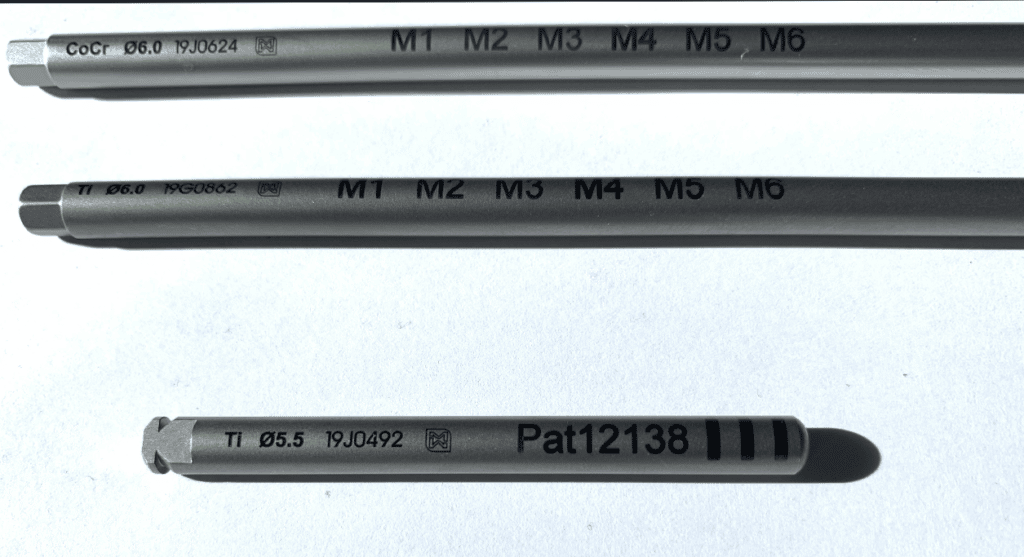

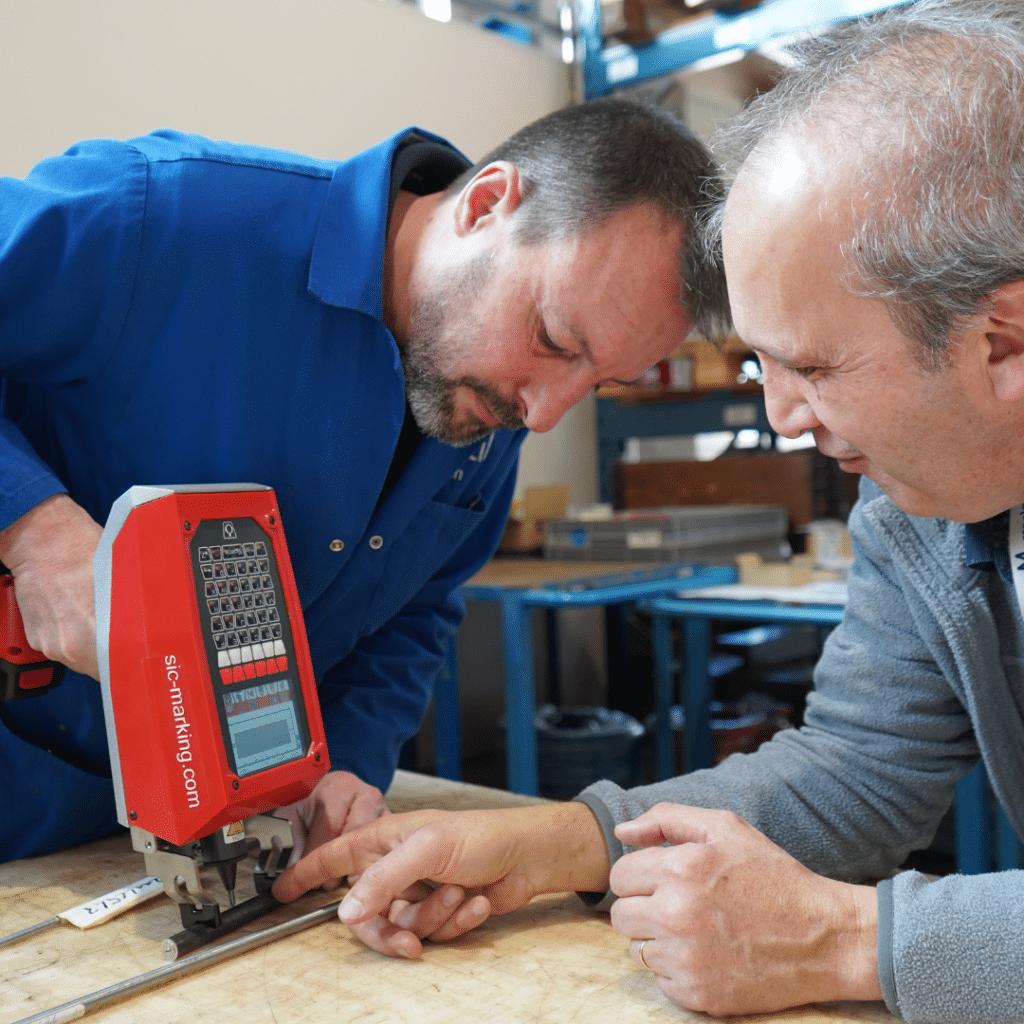

This marking is high-contrast and respects the implant’s mechanical properties.

The client cautions against the risk of breaking the surface during marking and shares their concerns about altering the material’s properties.

As a result, software to produce a unique marking on each part with alphanumeric information and features and different references from one part to another, needs to be provided.

This software must allow the client’s data to be retrieved, in order to mark the implant in the right place.